Customer:

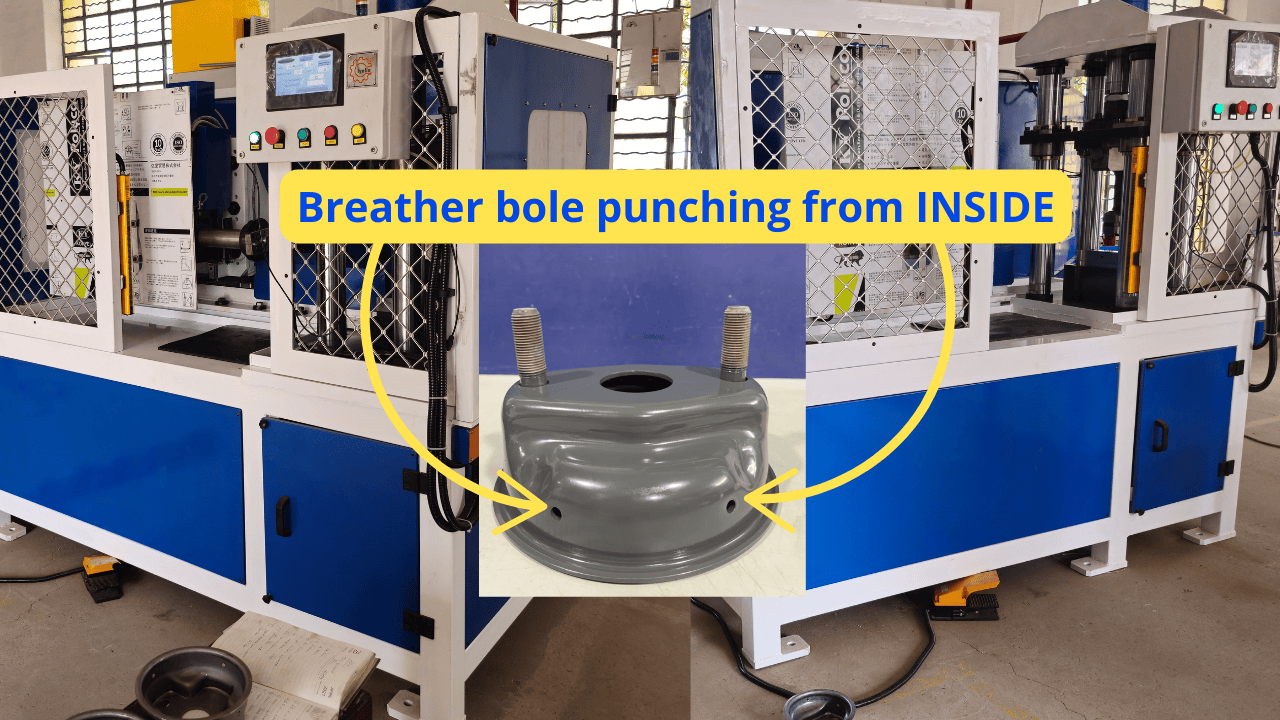

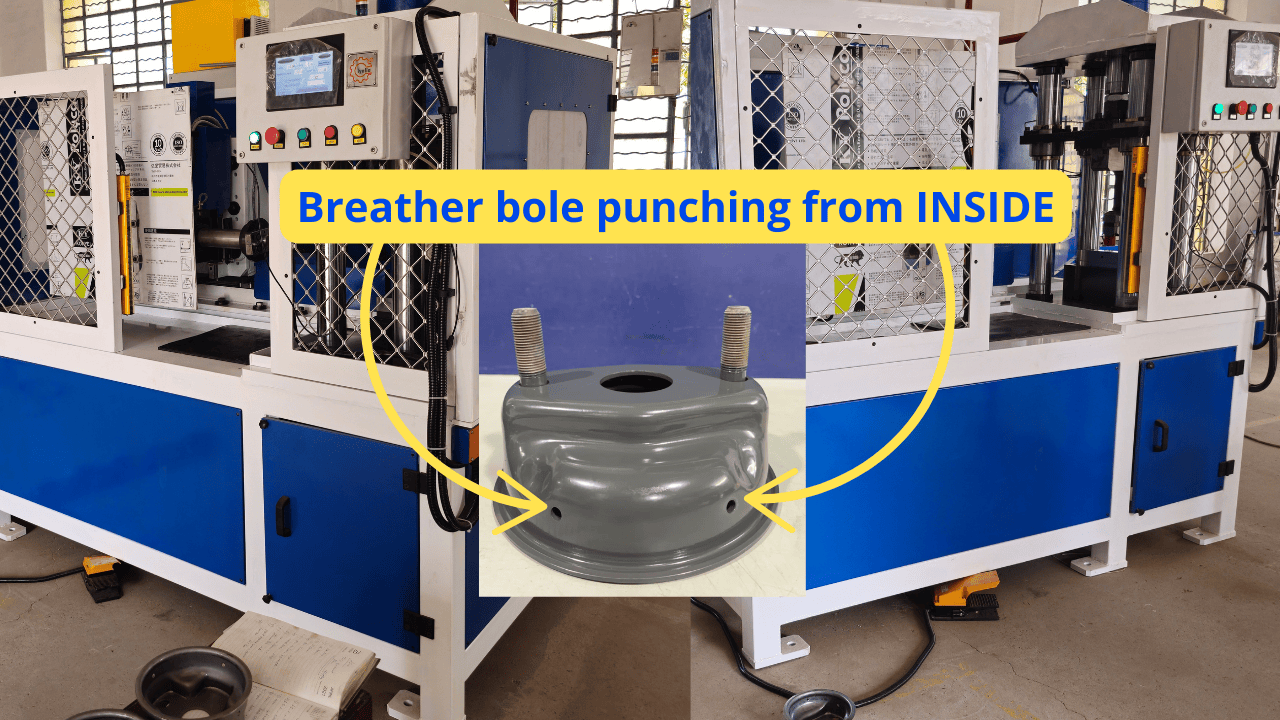

Breather Hole Punching SPM Servo Hydraulic

Project Category:

Servo and Hydraulic

Customer Requirement:

The Challenge: To design a fully automatic machine that could punch breather holes from the inside out, ensuring: ✔ No inward bending of sheet metal ✔ Clean, burr-free breather holes ✔ High-speed production with zero rejection

Project Result:

Inside-Out Hole Punching Technology | Zero Part Rejection | educed Cycle Time | First of its kind

What we did:

Iyalia SPM’s Innovative Solution Iyalia’s Breather Hole Punching Machine Iyalia SPM engineered a revolutionary solution: a servo-controlled, hydraulic punching system that creates breather holes from inside to out – a first-of-its-kind approach in the industry. Key Features of the Machine: ✅ Inside-Out Hole Punching Technology – Unlike traditional presses, our machine ensures that the metal flow moves outward, eliminating burr-related issues. ✅ Fully Servo-Controlled with Hydraulic Punching – Delivers high precision and repeatability. ✅ Customizable Hole Size, Degree, & Position – The operator simply enters the hole diameter, angle, and number of holes into the HMI (Human Machine Interface). ✅ Fully Automatic Process – The operator only fixes the part in the spindle, and the machine takes care of: Automatic clamping of the component Precision movement to the programmed location Accurate hole punching as per drawing specifications ✅ Interchangeable Punch & Die System – Hole size can be changed by simply replacing the punch and die set. ✅ Cycle Time: 20-30 Seconds – Achieved complete punching within the required time frame. ✅ Easy to Operate & Train – Any worker can be trained in under 30 minutes. Results Achieved 🚀 Zero Part Rejection – Not a single part failed quality checks after using Iyalia’s machine. 🚀 Eliminated Safety Risks – The inside-out punching method ensured that the diaphragm moves freely without damage. 🚀 Reduced Cycle Time – Achieved faster punching (20-30 seconds), improving productivity. 🚀 Improved Profitability – Fewer rejections and faster output led to higher efficiency and cost savings. 🚀 Customer’s Confidence in Iyalia – The success of this machine led to the customer placing orders for a third machine. Industry First: A Game-Changer in Sheet Metal Hole Punching While most manufacturers focused on reducing burrs and chamfering, Iyalia redefined the approach by changing the punching direction, making it the only solution of its kind globally. Why Choose Iyalia SPM? 🔹 Pioneering Innovation – We design customized SPMs that solve industry-specific challenges. 🔹 High-Precision Automation – Our machines use servo & hydraulic controls for unmatched accuracy. 🔹 Cost-Effective Manufacturing – Faster cycle times reduce operational costs & manpower dependency. 🔹 Industry-Leading Expertise – We specialize in tailor-made SPMs for the auto, industrial, and heavy machinery sectors. if you want to see the machine video, please call or email us.

Project Description

Customer Requirement & Challenge The company faced a critical issue in breather hole punching for their brake drums. The Problem: The traditional method of punching breather holes in sheet metal brake drums caused the metal to bend inward during the press operation. This bending created two major risks: Interference with the diaphragm – The diaphragm moves forward and backwards during braking. Any obstruction could cause malfunctioning. Sharp Metal Flow & Burr Formation – If the metal flow and burrs were not chamfered, they could cut the diaphragm, leading to serious safety hazards in heavy-load vehicles.

Project Budget:

2100000

Completion Date:

2023-12-15T00:00:00