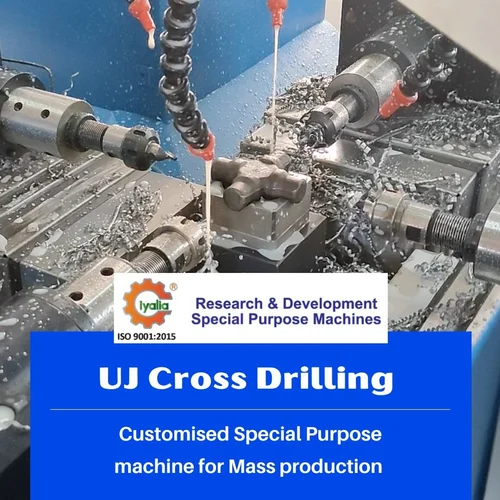

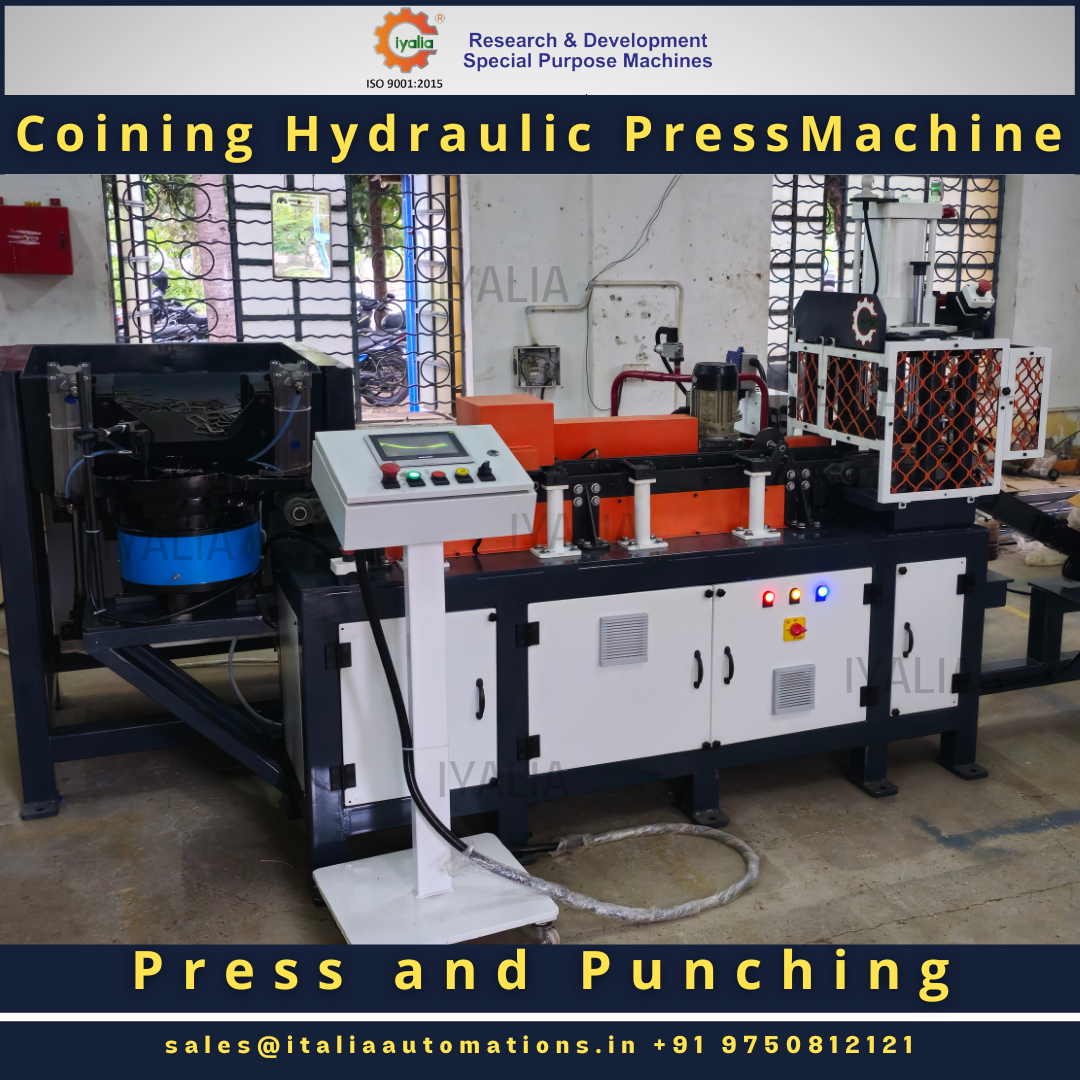

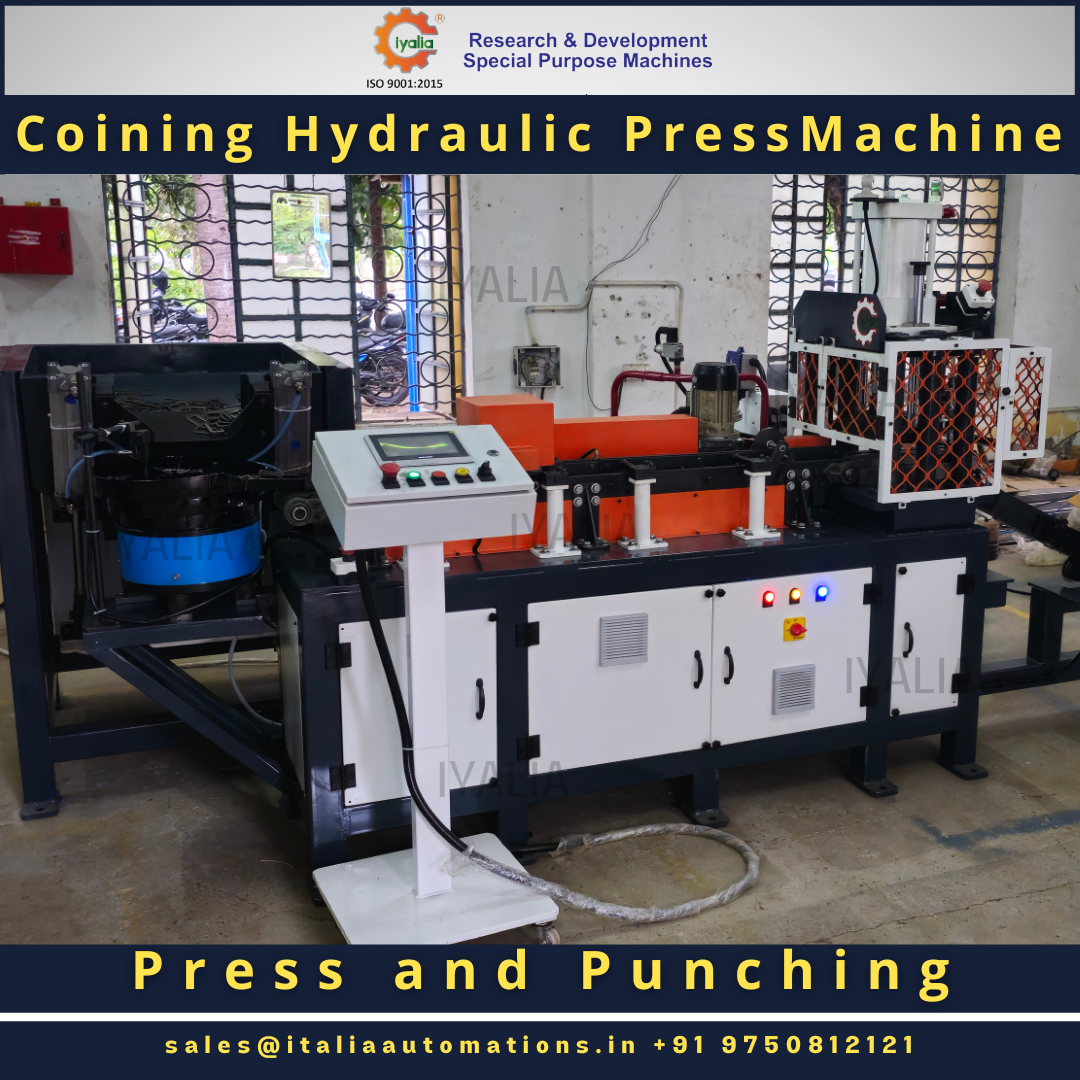

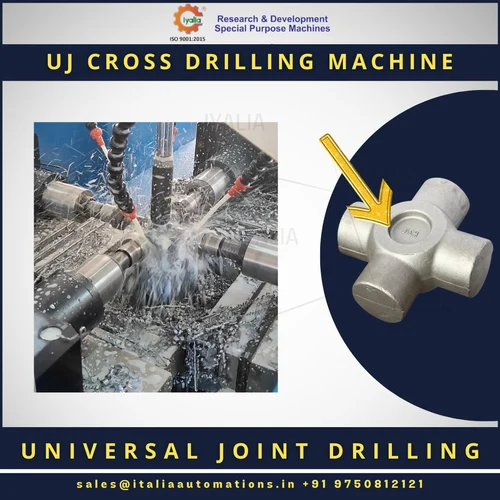

Drilling Tapping Machine| Iyalia Iyalia Drilling and Tapping Machine: Elevate Production 4X with Advanced SPM Drilling Looking to supercharge your Drilling Tapping processes? The Iyalia Drilling and Tapping Machine is your clear choice. Engineered as a high-performance Multi Drilling Tapping machine, it delivers production rates up to four times faster than standard drilling machines—while maintaining impeccable precision. From overcoming manpower challenges to maximizing ROI, Iyalia has you covered. Faster Production, Consistent Quality Speed is king in modern manufacturing. This SPM Drilling solution automates repetitive tasks, slashes cycle times, and ensures uniform holes and threads. You’ll eliminate production bottlenecks, meet urgent deadlines, and guarantee unwavering quality in every piece—essential for building a reputation of excellence in today’s competitive market. Overcome Manpower Challenges Worried about labor shortages or high turnover? By integrating this Multi Drilling machine, you reduce the strain on human resources. The intuitive interface requires minimal training, and automated functions lower manual intervention. Your team stays focused on strategic, high-value activities while enjoying a safer, more efficient work environment. Maximize ROI, Minimize Costs Investing in the Iyalia Drilling and Tapping Machine translates into tangible financial gains. With 4X faster Drilling Tapping output, you boost your throughput without adding extra shifts or personnel. Less downtime and durable components keep maintenance costs low, while improved accuracy cuts material waste. The result? A quicker path to breaking even and a robust return on investment. Scalable, Future-Ready Design Manufacturing demands shift fast. The Iyalia machine’s modular construction makes it adaptable—perfect for new materials or evolving product lines. Seamlessly integrate it with existing processes for higher-volume production, or upgrade its capabilities to match new market trends. You’ll stay agile and maintain a competitive edge. Why Choose the Iyalia Multi Drilling Tapping Machine? 4X higher throughput than standard drilling systems Precise SPM Drilling for consistently accurate holes and threads User-friendly controls that streamline training Reduced reliance on manual labor, boosting safety and morale Proven ROI with faster production and minimal downtime Ready to Transform Your Production? Celebrate the power of advanced Drilling Tapping technology and take your operations to unprecedented levels of efficiency. Contact us today to discover how the Iyalia Drilling and Tapping Machine—your trusted Multi Drilling machine—delivers game-changing performance, cuts overhead, and positions you for success in a rapidly evolving industry.

Send Message