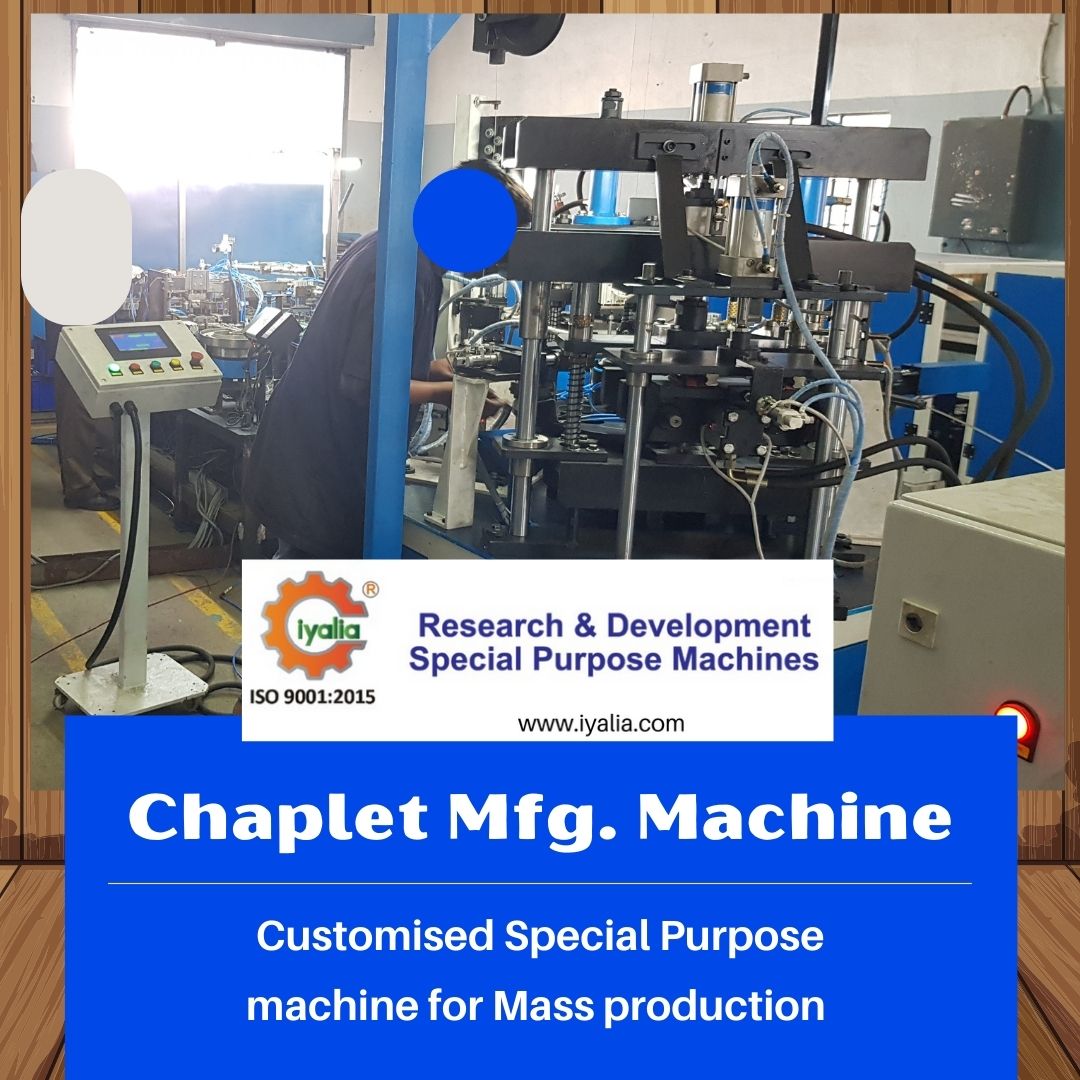

We make a Chaplet manufacturing machine where chaplets are made in 5 seconds with a single human resource;

Chaplet A is a small metal insert or spacer used in moulds which provides core support while the casting process is done.

Fast production: The machine can produce chaplets in just 5 seconds, making it a highly efficient and time-saving solution for manufacturers.

No manpower required: The machine is fully automated, which means that it can operate without any need for human intervention, reducing labour costs.

High accuracy: The machine is designed to produce chaplets with high precision and consistency, ensuring that every chaplet is of the same quality.

Easy to operate: The machine is user-friendly, with a simple interface of multiple operation that makes it easy for operators to use.

Low maintenance: The machine requires minimal maintenance, which makes it a cost-effective solution for manufacturers.

Durable: The machine is made from high-quality materials and is built to last longer, making it a reliable investment for any manufacturer.

Versatile: The machine can produce different types and sizes of chaplets, making it a versatile solution for a wide range of casting applications.

Safe: The machine is designed with safety in mind, as hydrauic press is involved with features such as emergency stop buttons and electrical safety guards to protect operators.

Efficient use of space: The machine has a compact design, which means that it takes up less space in the factory, allowing manufacturers to make the most of their available space.

Cost-effective: The machine is a cost-effective solution for manufacturers, as it can produce chaplets at a lower cost than traditional methods.

Improved productivity: The machine can help manufacturers increase their productivity by producing chaplets at a faster rate and with less labour.

Consistent quality: The machine produces chaplets with a consistent quality, which means that manufacturers can produce high-quality castings with a lower risk of defects.

Environmentally friendly: The machine is designed to be energy-efficient, which means that it consumes less energy and reduces the manufacturer's carbon footprint.

Faster lead times: The machine can produce chaplets faster than traditional methods, which means that manufacturers can reduce their lead times and deliver products to their customers faster.

Customizable: This particular Chaplet making machine cis customisable to meet the specific needs of different manufacturers, allowing them to produce chaplets that are tailored to their unique casting processes.

Hydraulic power: Hydraulic power is generated by using a hydraulic pump to move hydraulic fluid (usually oil) through a series of hoses and cylinders. The fluid is pressurized, which creates force that can be used to power the machine's various functions. In the chaplet manufacturing machine, hydraulic power might be used to control the movement of molds, the insertion of metal into the molds, or the ejection of finished chaplets.

Pneumatic power: Pneumatic power is generated by using compressed air to move pistons and cylinders. The compressed air is stored in a tank and released in controlled bursts to create force. In the chaplet manufacturing machine, pneumatic power might be used to control the movement of clamps or grippers, the rotation of molds, or the movement of finished chaplets out of the machine.

Keywords

oil

mind

tank

sizes

molds

hoses

force

clamps

bursts

moulds

spacer

series

pistons

defects

factory

grippers

manpower

features

rotation

products

movement

ejection

customers

5 seconds

cylinders

Chaplet A

operators

investment

lower risk

less space

lower cost

wide range

consistency

less energy

faster rate

less labour

core support

labour costs

same quality

Efficient use

High accuracy

high precision

compact design

compressed air

hydraulic pump

specific needs

available space

Pneumatic power

hydraulic fluid

Hydraulic power

Fast production

different types

Low maintenance

simple interface

carbon footprint

various functions

finished chaplets

Faster lead times

small metal insert

human intervention

particular Chaplet

Consistent quality

multiple operation

versatile solution

traditional methods

minimal maintenance

time-saving solution

casting applications

Improved productivity

single human resource

high-quality castings

high-quality materials

emergency stop buttons

different manufacturers

cost-effective solution

electrical safety guards

unique casting processes

Chaplet manufacturing machine