Keywords

hole sizes

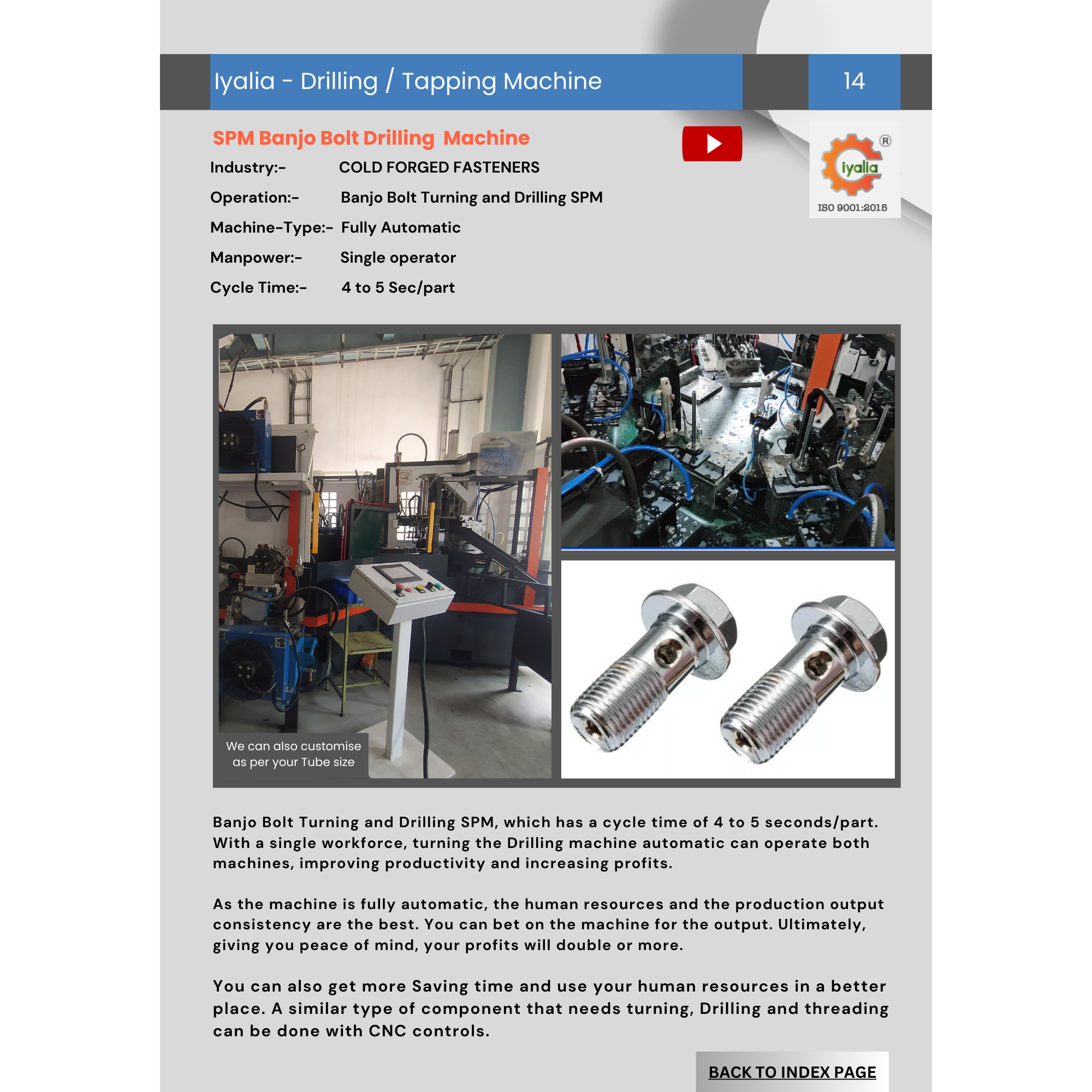

cycle time

one machine

bottom line

lower costs

floor space

SPM Drilling

Cost Savings

machine costs

one operation

three factors

two processes

Servo Controls

higher profits

Auto Components

multiple setups

tapping sequences

superior precision

energy consumption

Dual Functionality

standout offerings

production process

machine performance

Minimal Setup Times

tapping requirements

strategic investment

operational efficiency

high-volume industries

high-volume production

Custom Tooling Options

Tapping Machines Matter

specific material types

Productivity Enhancements

different production runs

other general engineering

multi-spindle configurations

overall operational expenses

varied production environments

consistent, repeatable results

automated, programmable drilling