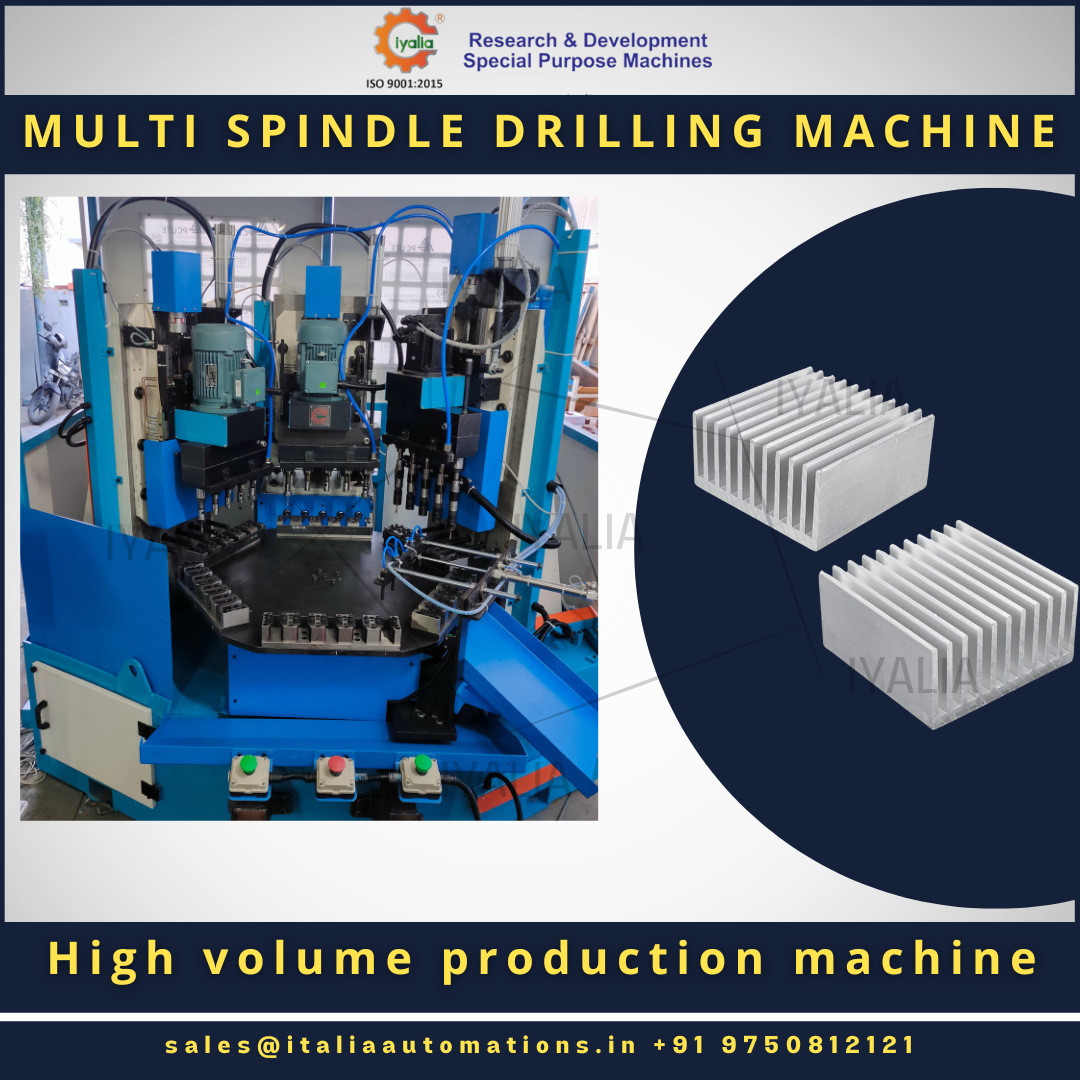

IYALIA Multi Spindle Drilling and Tapping Machine: A Revolutionary Machine for Efficient Drilling and Tapping Processes

Introduction: The IYALIA evolution of technology has led to numerous advanced machines and tools to enhance manufacturing processes. The multi-spindle drilling and tapping machine is an excellent example of such a technological marvel. This Technical machine article aims to delve into the workings of this machine, focusing on its ability to perform drilling and tapping operations simultaneously while emphasizing the efficiency brought about by its rotary table design.

I. Overview of the Multi-Spindle Drilling and Tapping Machine A. Definition and Purpose The multi-spindle drilling and tapping machine, as the name suggests, is a specialized Machine used in industrial parts manufacturing. It is designed to perform multiple drilling and tapping operations concurrently, utilizing a rotary table mechanism and vertical alignment of drill and tapping heads.

B. Key Components

Rotary Table: Significantly contributes to the machine's efficiency by providing precise indexing and positioning capabilities, ensuring accurate processing.

Drilling Head: Composed of several spindles, each housing a drill bit. The number of drill heads can vary depending on the specific machine model.

Tapping Heads: Consists of multiple spindles, each fitted with tapping tools. The tapping heads are vital in facilitating threading operations during the process.

II. Working Principles and Features of Multi-Spindle Drilling and Tapping Machine A. Vertical Alignment The multi-spindle drilling and tapping machine adopts a vertical alignment configuration, whereby the drilling heads and tapping heads are aligned vertically. This arrangement optimizes the machine's footprint, making it a compact, space-saving solution for drilling and tapping requirements.

B. Simultaneous Drilling and Tapping The primary advantage of this machine is its ability to perform drilling and tapping operations simultaneously. Combining these processes in one machine streamlines manufacturing processes, reducing production time and costs.

C. Rotary Table Design Incorporating a rotary table enables precise rotational movement, offering accuracy and stability during indexing. The rotary table's mechanism ensures consistent positioning, allowing for accurate drilling and tapping at different workstations without manual intervention.

D. Counter for Drill and Tapping The machine's advanced features include a built-in counter system that accurately tracks the number of drilling and tapping cycles completed. This function aids in monitoring production progress and ensures the maintenance of desired quality and uniformity throughout the manufacturing process.

III. Applications and Benefits of Multi-Spindle Drilling and Tapping Machine A. Mass Production on a Large Scale The multi-spindle drilling and tapping machine excels in high-volume production settings. With simultaneous drilling and tapping capabilities and the capacity to handle multiple workstations, this machine significantly boosts production rates.

B. Enhanced Efficiency and Productivity Incorporating a counter system and eliminating manual workstations allow for increased efficiency and productivity. Manufacturers can optimize their production processes by reducing human errors, minimizing downtime, and achieving greater output.

C. Improved Accuracy and Quality Control The vertical alignment of the drill and tapping heads, coupled with the precision offered by the rotary table mechanism, ensures accurate positioning and consistent drilling and tapping results. This enhances product quality and reduces rework, thus improving overall quality control.

D. Versatility and Adaptability: The multi-spindle drilling and tapping machine can be customized to accommodate different materials, geometries, and hole sizes. It allows manufacturers to adapt to varying production requirements or you can say outputs in a shift, making it a valuable asset in diverse industries.

IV. Conclusion The multi-spindle drilling and tapping machine has revolutionized the manufacturing industry by offering unique drilling and tapping capabilities. With its rotary table design, vertical alignment, and exceptional productivity, this advanced machine enhances production efficiency while ensuring accuracy and consistent quality. This revolutionary tool paves the way for increased productivity and ROI (profitability) across various industries by minimizing manual workstations and optimizing performance.

Keywords

way

ROI

name

asset

shift

costs

number

rework

ability

Purpose

outputs

function

downtime

capacity

Benefits

Consists

workings

accuracy

precision

increased

drill bit

footprint

technology

hole sizes

uniformity

geometries

D. Counter

Large Scale

drill heads

one machine

performance

I. Overview

maintenance

arrangement

Applications

human errors

Introduction

Drilling Head

tapping heads

tapping tools

Manufacturers

D. Versatility

tapping cycles

greater output

IV. Conclusion

counter system

production time

unique drilling

tapping results

product quality

several spindles

IYALIA evolution

production rates

precise indexing

excellent example

advanced features

B. Key Components

primary advantage

accurate drilling

multiple spindles

Tapping Processes

multiple drilling

consistent quality

Efficient Drilling

revolutionary tool

various industries

diverse industries

A. Mass Production

tapping operations

Working Principles

specialized Machine

consistent drilling

manual intervention

different materials

production progress

manual workstations

accurate processing

tapping requirements

production processes

threading operations

technological marvel

tapping capabilities

accurate positioning

multiple workstations

Revolutionary Machine

production efficiency

different workstations

C. Rotary Table Design

specific machine model

consistent positioning

rotary table mechanism

multi-spindle drilling

manufacturing industry

overall quality control

manufacturing processes

B. Simultaneous Drilling

exceptional productivity

positioning capabilities

Technical machine article

numerous advanced machines

precise rotational movement

Tapping Machine A. Definition

IYALIA Multi Spindle Drilling

compact, space-saving solution

industrial parts manufacturing

varying production requirements

high-volume production settings

vertical alignment configuration