Keywords

CEO

ROI

return

context

company

Funding

insights

products

decision

training

purchase

employees

precision

customers

Budgeting

capability

labor costs

new markets

performance

perspective

integration

consistency

new machine

improvements

advancements

Productivity

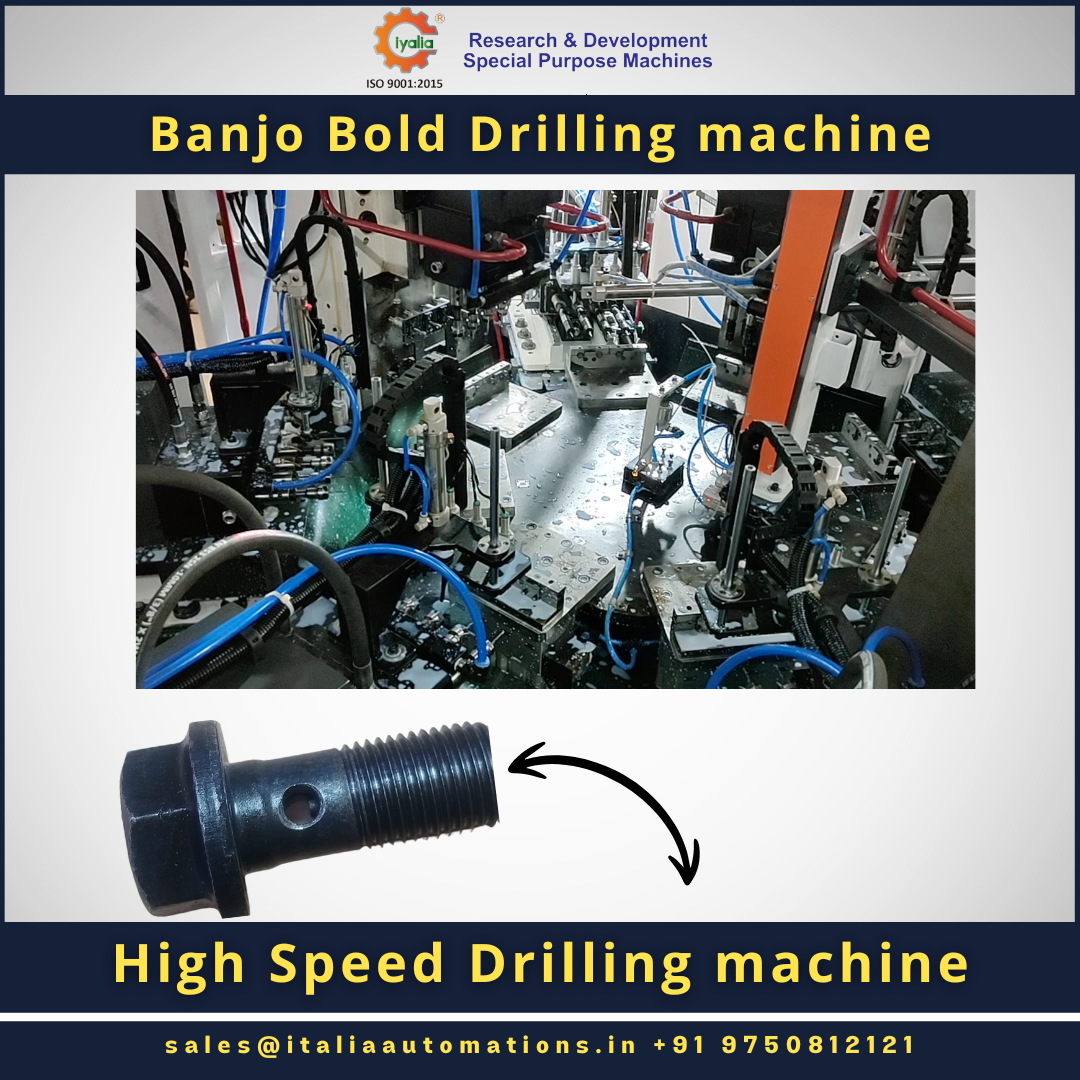

SPM drilling

output rates

complex parts

reduced costs

Market Demand

market trends

product design

overall vision

Cost Reduction

new technology

product quality

tapping machine

Risk Management

ongoing support

Market Position

long-term value

Strategic Growth

production costs

financial health

customer demands

competitive edge

job satisfaction

brand reputation

quality standards

investment should

customer feedback

increased loyalty

customer segments

operational costs

installation phase

sustainable growth

existing processes

immediate benefits

innovation strategy

financial stability

industry reputation

production capacity

future requirements

Environmental Impact

Supplier Reliability

development programs

sustainability goals

lower material waste

efficient energy use

increased efficiency

production efficiency

existing market needs

Competitive Advantage

Mass production parts

best financing options

Operational Efficiency

environmental benefits

Continuous Improvement

manufacturing processes

Special Purpose Machine

strategic considerations

Financial Considerations

broader strategic vision

Corporate Responsibility

New Market Opportunities

reduced energy consumption

new business opportunities

manufacturing capabilities

Machine Strategic Alignment

customer satisfaction goals

long-term growth objectives

Employee Skills Development

potential operational risks

Positive customer experiences

manufacturing Engineering part

thorough cost-benefit analysis