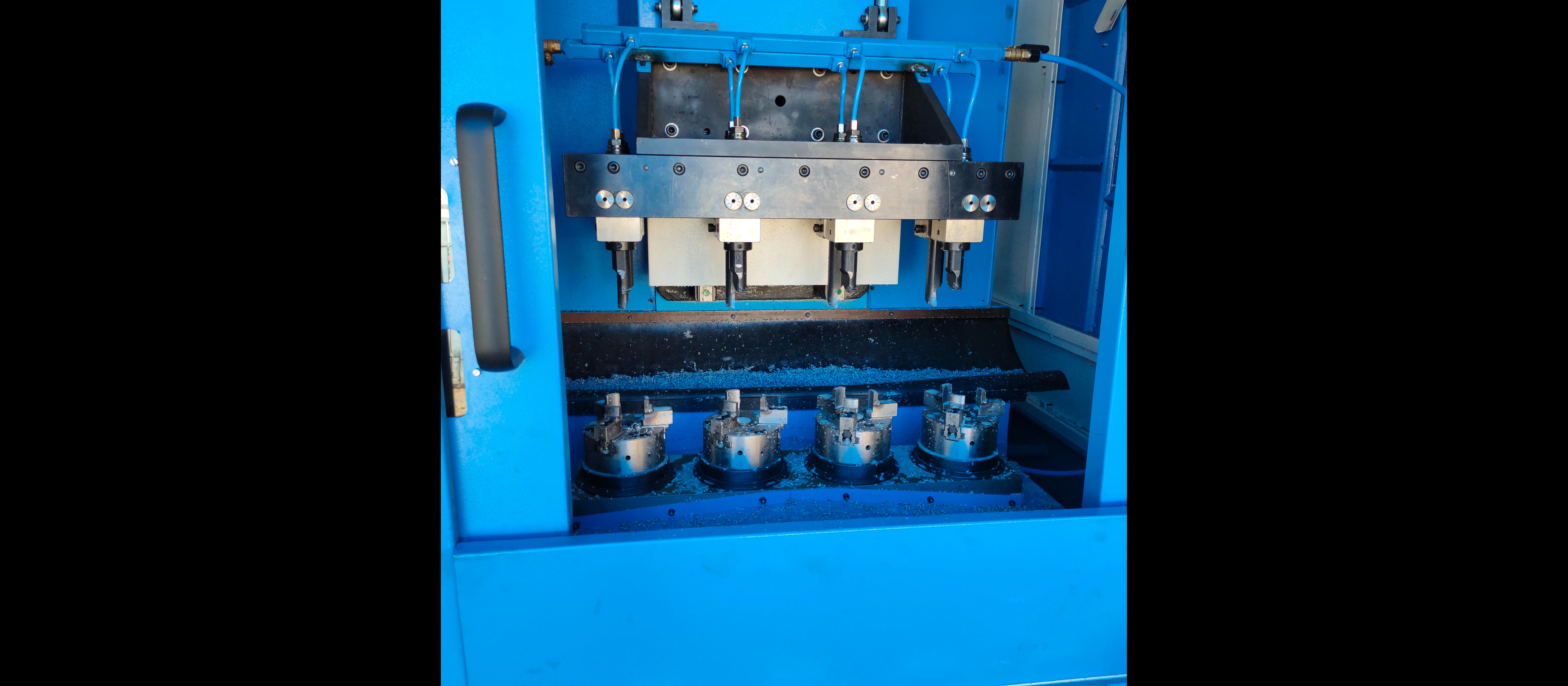

Feedback from a customer:- Embracing the Future of Manufacturing of pre-drilling In the heart of the manufacturing industry, end-users like myself face a daily gauntlet of challenges. From meeting tight production deadlines to ensuring each piece meets the highest quality standards, the pressure is relentless. Our ability to stay competitive hinges on the efficiency and reliability of our machinery. That's where the SPM Drilling Machine comes into play. A beacon of innovation in a traditional field, it promises to redefine our approach to manufacturing. First Impressions: Encountering the SPM Drilling Machine The first encounter with the SPM Drilling Machine was akin to glimpsing the future of manufacturing. Its four spindles, impressive 30mm drilling capacity, and cutting-edge Servo Technology promised a level of productivity and precision previously unattainable. Given the bold claims, scepticism was natural, but the machine's specifications spoke volumes. It was clear from the outset that this was not just another piece of equipment but a leap forward. Ease of Use: Demystifying the Technology The transition to using the SPM Drilling Machine was surprisingly smooth. Its intuitive user interface and straightforward setup process quickly dispelled initial apprehensions about its complexity. The learning curve was gentle, facilitated by comprehensive training and support from the manufacturer. It was refreshing to encounter such a powerful machine that did not sacrifice user-friendliness for the sake of advanced features. Operational Efficiency: A Game-Changer on the Floor The impact of the SPM Drilling Machine on our workflow was immediate and profound. Tasks previously consumed hours were completed in minutes without compromising precision or quality. The capability to machine four parts in a single stroke dramatically accelerated our production cycle, enabling us to quickly meet demanding deadlines. Moreover, the consistency and accuracy of the parts produced were unparalleled, significantly reducing the time spent on quality control and rework. Reliability and Maintenance: Building Trust Through Performance The actual test of any machinery lies in its reliability and ease of maintenance. The SPM Drilling Machine has proven to be a steadfast ally on the manufacturing floor. Its robust design and advanced technology ensure minimal downtime, while regular maintenance is simplified by its user-friendly architecture. Support from the manufacturer has been exemplary, with prompt responses and effective solutions being the norm, fostering a sense of confidence in the machine's long-term performance. Comparative Analysis: Outshining the Old Guard Compared to the previous equipment we relied on, the SPM Drilling Machine stands in a league of its own. Traditional machines required multiple setups and operator interventions, increasing production times and variability in part quality. The shift to the SPM Drilling Machine has enhanced productivity and improved the overall user experience. The difference is night and day, with the new machine offering a seamless, efficient, and more enjoyable work process. Conclusion: Reflecting on a Revolutionized Workday Reflecting on the journey since introducing the SPM Drilling Machine into our operations, it's clear that it has fundamentally transformed my workday. A confident assurance in our production capabilities has replaced the dread of unmet deadlines and compromised quality. This machine has not just improved our workflow; it has elevated our standards and expectations for what is possible in manufacturing. Looking to the future, I am excited about the prospects of further innovations and how they will continue to reshape our industry. The SPM Drilling Machine is not just a tool; it's a harbinger of the future, and I am here for it.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2024-04-08T04:00:12

Feedback from a customer:- Embracing the Future of Manufacturing of pre-drilling In the heart of the manufacturing industry, end-users like myself face a daily gauntlet of challenges. From meeting tight production deadlines to ensuring each piece meets the highest quality standards, the pressure is relentless. Our ability to stay competitive hinges on the efficiency and reliability of our machinery. That's where the SPM Drilling Machine comes into play. A beacon of innovation in a traditional field, it promises to redefine our approach to manufacturing. First Impressions: Encountering the SPM Drilling Machine The first encounter with the SPM Drilling Machine was akin to glimpsing the future of manufacturing. Its four spindles, impressive 30mm drilling capacity, and cutting-edge Servo Technology promised a level of productivity and precision previously unattainable. Given the bold claims, scepticism was natural, but the machine's specifications spoke volumes. It was clear from the outset that this was not just another piece of equipment but a leap forward. Ease of Use: Demystifying the Technology The transition to using the SPM Drilling Machine was surprisingly smooth. Its intuitive user interface and straightforward setup process quickly dispelled initial apprehensions about its complexity. The learning curve was gentle, facilitated by comprehensive training and support from the manufacturer. It was refreshing to encounter such a powerful machine that did not sacrifice user-friendliness for the sake of advanced features. Operational Efficiency: A Game-Changer on the Floor The impact of the SPM Drilling Machine on our workflow was immediate and profound. Tasks previously consumed hours were completed in minutes without compromising precision or quality. The capability to machine four parts in a single stroke dramatically accelerated our production cycle, enabling us to quickly meet demanding deadlines. Moreover, the consistency and accuracy of the parts produced were unparalleled, significantly reducing the time spent on quality control and rework. Reliability and Maintenance: Building Trust Through Performance The actual test of any machinery lies in its reliability and ease of maintenance. The SPM Drilling Machine has proven to be a steadfast ally on the manufacturing floor. Its robust design and advanced technology ensure minimal downtime, while regular maintenance is simplified by its user-friendly architecture. Support from the manufacturer has been exemplary, with prompt responses and effective solutions being the norm, fostering a sense of confidence in the machine's long-term performance. Comparative Analysis: Outshining the Old Guard Compared to the previous equipment we relied on, the SPM Drilling Machine stands in a league of its own. Traditional machines required multiple setups and operator interventions, increasing production times and variability in part quality. The shift to the SPM Drilling Machine has enhanced productivity and improved the overall user experience. The difference is night and day, with the new machine offering a seamless, efficient, and more enjoyable work process. Conclusion: Reflecting on a Revolutionized Workday Reflecting on the journey since introducing the SPM Drilling Machine into our operations, it's clear that it has fundamentally transformed my workday. A confident assurance in our production capabilities has replaced the dread of unmet deadlines and compromised quality. This machine has not just improved our workflow; it has elevated our standards and expectations for what is possible in manufacturing. Looking to the future, I am excited about the prospects of further innovations and how they will continue to reshape our industry. The SPM Drilling Machine is not just a tool; it's a harbinger of the future, and I am here for it.

2024-04-08T04:00:12

Keywords

- play

- leap

- Ease

- tool

- sake

- norm

- level

- piece

- Tasks

- heart

- hours

- Trust

- sense

- shift

- night

- dread

- beacon

- league

- impact

- rework

- outset

- Future

- ability

- journey

- volumes

- minutes

- support

- pressure

- customer

- approach

- workflow

- accuracy

- Feedback

- precision

- end-users

- prospects

- machinery

- harbinger

- Old Guard

- scepticism

- operations

- Conclusion

- innovation

- difference

- four parts

- confidence

- challenges

- transition

- complexity

- bold claims

- new machine

- consistency

- actual test

- manufacturer

- Game-Changer

- part quality

- expectations

- productivity

- four spindles

- robust design

- single stroke

- daily gauntlet

- specifications

- steadfast ally

- learning curve

- first encounter

- unmet deadlines

- multiple setups

- quality control

- powerful machine

- production cycle

- production times

- minimal downtime

- prompt responses

- advanced features

- user-friendliness

- traditional field

- First Impressions

- previous equipment

- effective solutions

- manufacturing floor

- confident assurance

- regular maintenance

- demanding deadlines

- advanced technology

- Comparative Analysis

- Traditional machines

- initial apprehensions

- long-term performance

- enjoyable work process

- operator interventions

- Operational Efficiency

- Revolutionized Workday

- comprehensive training

- manufacturing industry

- overall user experience

- production capabilities

- intuitive user interface

- The SPM Drilling Machine

- highest quality standards

- user-friendly architecture

- tight production deadlines

- cutting-edge Servo Technology

- straightforward setup process

- impressive 30mm drilling capacity

Submit Your Enquiry