Boost Efficiency with a Multi-Spindle Drilling Machine for Banjo Bolts with a 5-Second Cycle Time.

Introduction: Regarding precision drilling in the manufacturing industry, speed, accuracy, and Efficiency are critical factors for success. The Multi Spindle Drilling Machine for Banjo Bolts, with a part to part cycle time of just 5 seconds, is an innovative solution that can revolutionize your production processes. In this SEO-optimized content piece, we will explore this cutting-edge machine's features, benefits, and applications.

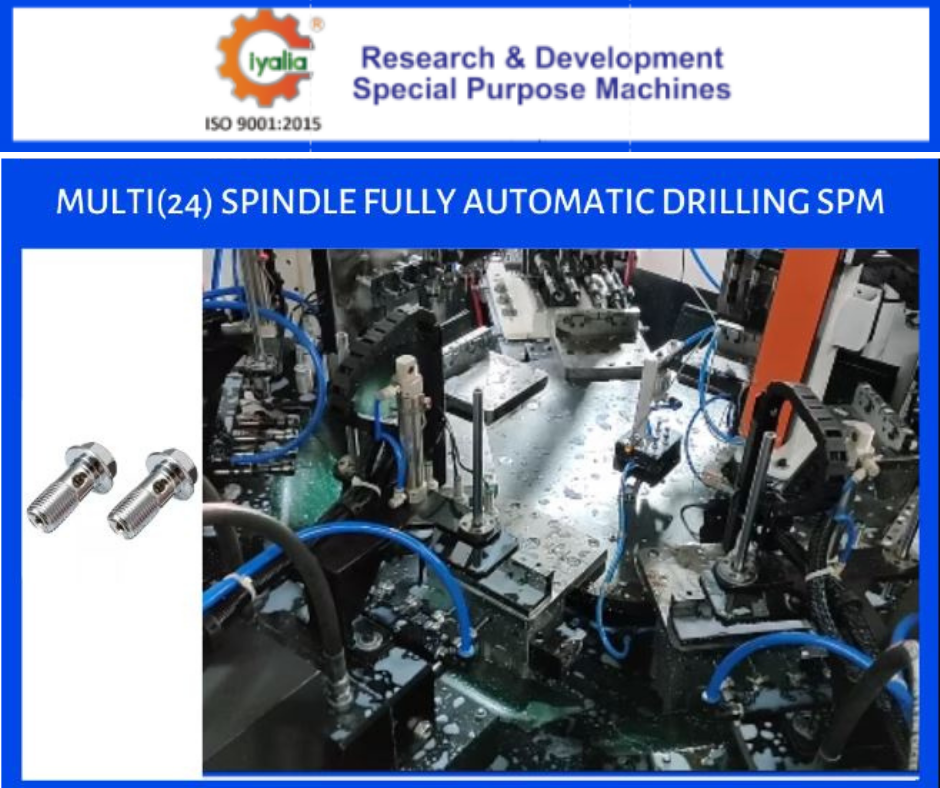

What is a Multi-Spindle Drilling Machine for Banjo Bolts? A Multi Spindle Drilling Machine for Banjo Bolts is a specialized equipment designed to swiftly and accurately drill multiple holes in banjo bolts, crucial components in various automotive, hydraulic, and plumbing industries.

Features and Capabilities:

Speed and Precision: With its exceptional cycle time of 5 seconds, this machine can significantly increase drilling productivity while maintaining unmatched precision.

Multi-Spindle Configuration: Equipped with multiple drilling spindles, the machine can drill numerous holes in banjo bolts, significantly reducing production time.

Automated Drilling Process: The machine is engineered with advanced automation features, eliminating the need for manual intervention and reducing labour costs.

Customization Options: The system can be tailored to meet specific drilling requirements, such as hole diameter, hole depth, and bolt dimensions, ensuring versatility for various applications.

Benefits of Multi Spindle Drilling Machine for Banjo Bolts:

Enhanced Productivity: The high-speed drilling process reduces cycle time, enabling manufacturers to produce banjo bolts in larger quantities without compromising quality.

Improved Accuracy: The machine's precise drilling mechanism ensures consistent hole dimensions, minimizing the risk of errors or defective products.

Cost Savings: By automating the drilling process and optimizing Efficiency, this machine helps reduce labour costs and maximize overall production output.

Versatility: Whether you require different hole sizes, multiple hole patterns, or varied banjo bolt specifications, the machine's customizable features cater to different production needs.

Reliable Performance: Built with robust materials and advanced technology, the machine guarantees durability, minimal downtime, and a longer operational lifespan.

Applications: A Multi Spindle Drilling Machine for Banjo Bolts finds wide applications across industries such as:

Automotive: Facilitating the drilling of banjo bolts for fuel injectors, brake systems, and hydraulic cylinders.

Hydraulics: Drilling holes for fittings, connectors, and manifolds.

Plumbing: Assisting in producing banjo bolts for pipe fittings, valves, and fluid control systems.

Conclusion: Investing in a Multi Spindle Drilling Machine for Banjo Bolts with a cycle time of 5 seconds can revolutionize your manufacturing processes, offering unmatched speed, accuracy, and Efficiency. This cutting-edge equipment can propel your business ahead of the competition by reducing production time, increasing output, and ensuring optimal drilling precision. Embrace the power of advanced automation and unlock the full potential of banjo bolt production with this impressive machine.

Keywords

risk

power

valves

errors

success

quality

benefits

business

manifolds

5 seconds

Automotive

hole depth

Hydraulics

Efficiency

durability

Conclusion

connectors

competition

Banjo Bolts

versatility

labour costs

Capabilities

Introduction

Cost Savings

manufacturers

pipe fittings

hole diameter

brake systems

fuel injectors

full potential

multiple holes

numerous holes

bolt dimensions

production time

unmatched speed

part cycle time

critical factors

minimal downtime

robust materials

Improved Accuracy

wide applications

larger quantities

impressive machine

precision drilling

defective products

crucial components

hydraulic cylinders

plumbing industries

manual intervention

unmatched precision

innovative solution

5-Second Cycle Time

advanced technology

Reliable Performance

different hole sizes

production processes

cutting-edge machine

various applications

Customization Options

drilling productivity

customizable features

fluid control systems

specialized equipment

Enhanced Productivity

banjo bolt production

multiple hole patterns

exceptional cycle time

manufacturing industry

cutting-edge equipment

manufacturing processes

overall production output

consistent hole dimensions

optimal drilling precision

precise drilling mechanism

different production needs

Automated Drilling Process

multiple drilling spindles

high-speed drilling process

Multi-Spindle Configuration

longer operational lifespan

SEO-optimized content piece

advanced automation features

specific drilling requirements

Multi-Spindle Drilling Machine

varied banjo bolt specifications

A Multi Spindle Drilling Machine

The Multi Spindle Drilling Machine