Baler Spring Making Machine – High-Precision Manufacturing for Agricultural Spring Tines

Introduction

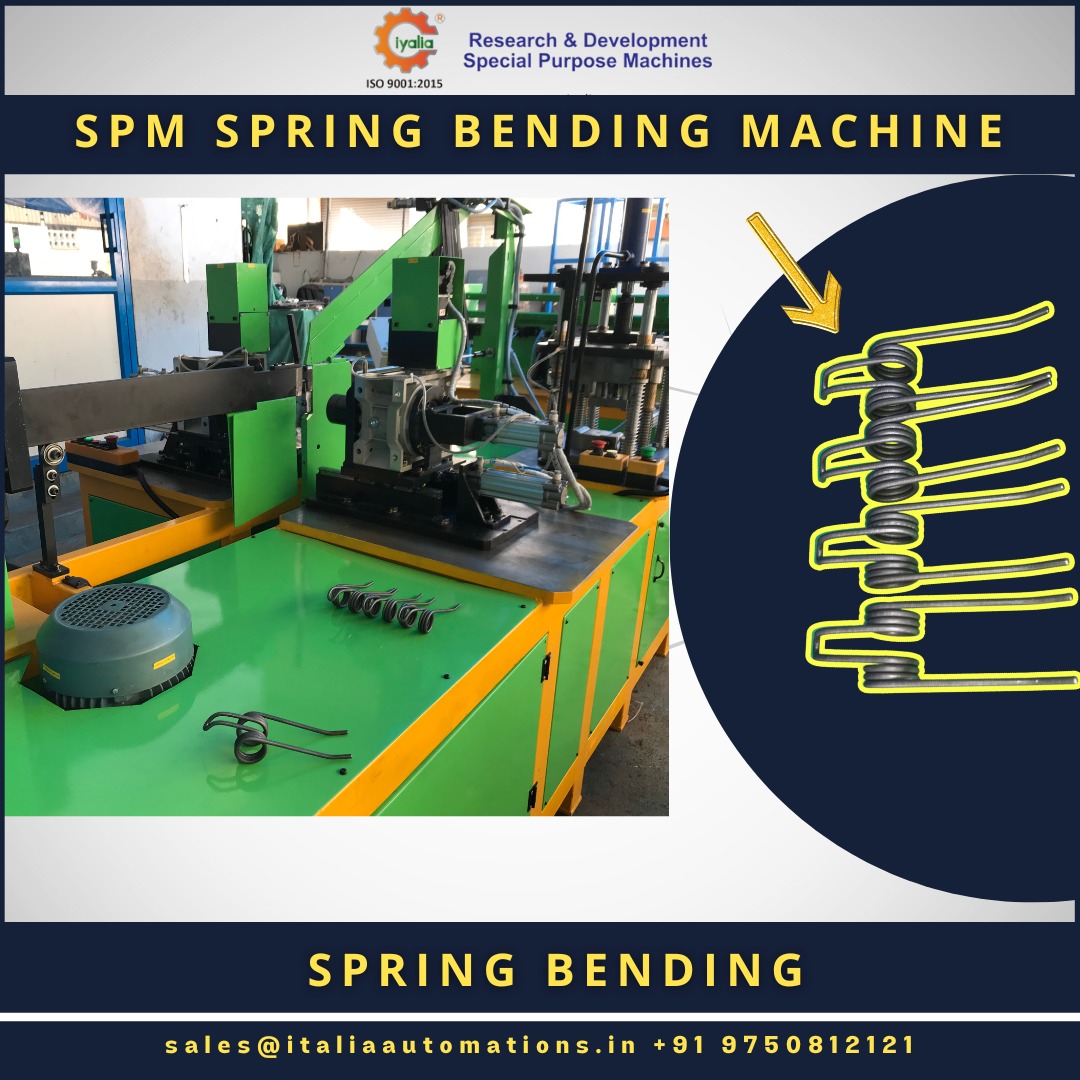

In modern agriculture, spring tines are essential components in baler machines and cultivators, helping to aerate the soil, reduce compaction, and remove weeds efficiently. To achieve superior durability and performance, these spring tines must be manufactured with precision and consistency. The Baler Spring Making Machine is a state-of-the-art system designed to produce high-quality double torsion spring tines with automated precision and efficiency.

This advanced machine ensures high-speed production, consistent bending accuracy, and minimal material wastage, making it an ideal solution for agricultural equipment manufacturers.

How the Baler Spring Making Machine Works

The Baler Spring Making Machine operates in a structured three-stage process, ensuring precision and efficiency at each step:

1. Initial Wire Feeding & Pre-Bending

A bulk feeder system loads and accelerates the spring steel wire into the machine.

The wire is automatically straightened and pre-bent into initial shapes using precision-controlled bending mechanisms.

The bent parts are collected before proceeding to the next stage.

2. Servo & Gearbox-Controlled Bending

The pre-bent parts are fed into the next section of the machine.

A servo system and gearbox mechanism precisely bend the springs according to pre-programmed specifications.

The completed spring parts are collected at the machine’s bottom, ensuring a smooth and automated process with minimal manual intervention.

3. Hydraulic Press for Final Bending & Shaping

In the final stage, the partially processed springs are fed manually into a hydraulic press for the final bending process.

This step ensures high accuracy and controlled shaping of each spring within set limits.

The finished springs are collected and inspected for quality assurance.

Key Features & Benefits of the Baler Spring Making Machine

✅ High Precision & Accuracy – Automated bending ensures uniform spring shapes with tight tolerances.

✅ Efficient Production Process – The three-stage operation allows for high-speed, bulk manufacturing.

✅ Servo & Gearbox Mechanism – Ensures smooth and precise bending for consistent results.

✅ Hydraulic Press Integration – Adds final shaping strength for durability and performance.

✅ Minimal Material Wastage – Optimized processing leads to cost-effective production.

✅ Suitable for Various Agricultural Spring Tines – Customizable for different tine diameters and lengths.