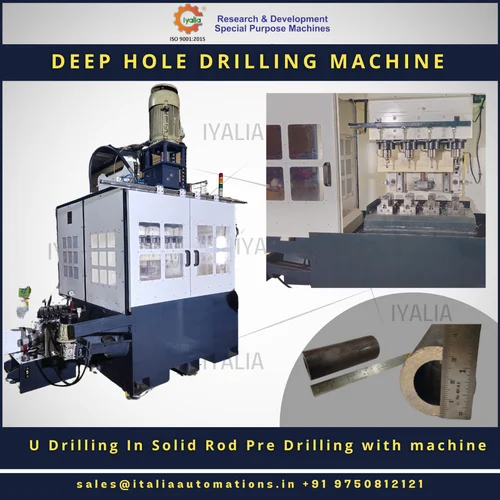

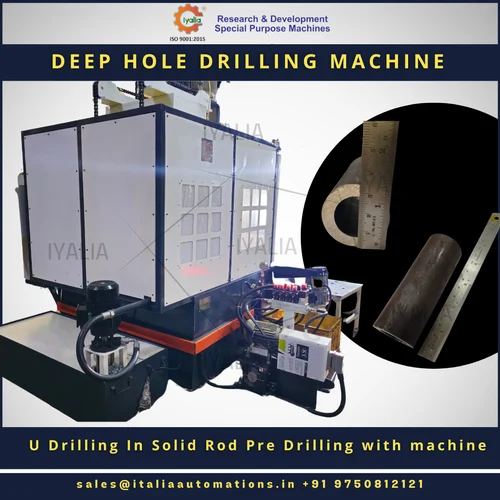

Pre Hole U Drilling with 4 spindle Overcoming Pre-Drilling Challenges with Iyalia Pre-Drilling Machine Pre-drilling in any metal, whether soft or hard, poses several manufacturing challenges, especially when using CNC machines, drilling machines, or lathes. The Iyalia Pre-Drilling machine offers a revolutionary solution to these challenges, providing significant benefits for manufacturers. Key Benefits of Iyalia Pre-Drilling Machine Enhanced Productivity Efficient Use of Space Reduced Labor Costs Time and Energy Savings Customer Satisfaction Increased Profitability Stress-Free Operations Revolutionize Your Manufacturing with Iyalia Pre-Drilling Machine Are you facing challenges in pre-drilling metal components with CNC machines, drilling machines, or lathes? The Iyalia Pre-Drilling machine is the perfect solution to enhance your productivity and efficiency. Our advanced machine is designed to handle pre-drilling in both soft and hard metals, overcoming common manufacturing hurdles with ease. Unmatched Productivity and Efficiency The Iyalia Pre-Drilling machine sets a new standard in manufacturing by allowing you to drill four components simultaneously. This not only boosts your productivity by four times but also ensures faster delivery times, helping you to meet tight deadlines as per customer expectations of productivity Optimize Your Workspace Space is a valuable asset in any manufacturing facility. The compact design of the Iyalia Pre-Drilling machine means you can maximize your floor space while still achieving high output. This optimization is crucial for businesses looking to expand their operations without the need for additional space. Reduce Labor Costs With the ability to handle the machine with just one operator, you can significantly reduce your labor costs. The machine’s efficiency eliminates the need for additional manpower, translating into substantial savings. Save Time and Energy Efficiency is key in manufacturing, and the Iyalia Pre-Drilling machine delivers by saving you time and energy. Its simultaneous processing capabilities streamline your operations, making your manufacturing process more efficient and less time-consuming. Delight Your Customers Timely delivery of the finished parts is very essential for maintaining customer satisfaction. The Iyalia Pre-Drilling machine ensures that your components are delivered on time, every time. This reliability boosts your reputation and keeps your customers coming back for more. Boost Your Profits The cost savings achieved through reduced labor, optimized space, and efficient operations directly impact your bottom line. Increased profitability will allows you to reinvest in your business, drive your business growth, and stay ahead of the competition. Enjoy a Tension-Free Manufacturing Experience Say goodbye to the stress and challenges of pre-drilling operations. With the Iyalia Pre-Drilling machine, you can enjoy a seamless, tension-free manufacturing experience. Our machine’s reliability and efficiency mean you can focus on what you do best – growing your business. Conclusion Invest in the Iyalia Pre-Drilling machine today and transform your manufacturing operations. Experience the benefits of higher productivity, reduced costs, and increased customer satisfaction. Live a better, tension-free life with the Iyalia Pre-Drilling machine, and watch your business thrive.

Send Message