Tapping machine

SPM Nut Tapping Machine| Iyalia

Revolutionizing Nut Tapping: How Servo-Based Tapping Machines Enhance Speed, Accuracy, and EfficiencyIntroduction

Nut tapping is a critical process in manufacturing, spanning industries such as automotive, aerospace, construction, and consumer electronics. With high demand and tight production schedules, manufacturers need high-speed, precision-driven solutions to stay competitive. However, conventional tapping machines often struggle with long cycle times, inconsistent thread quality, and high labor costs.

The Need for High-Speed Nut Tapping Machines

Manufacturers face multiple challenges in nut tapping operations:

✅ High Production Demand – Millions of nuts are used across industries, requiring rapid, high-volume tapping solutions.

✅ Precision & Consistency – Thread defects can lead to product failures, increasing rework and production costs.

✅ Cost-Effectiveness – Longer cycle times mean higher labor costs and reduced profitability.

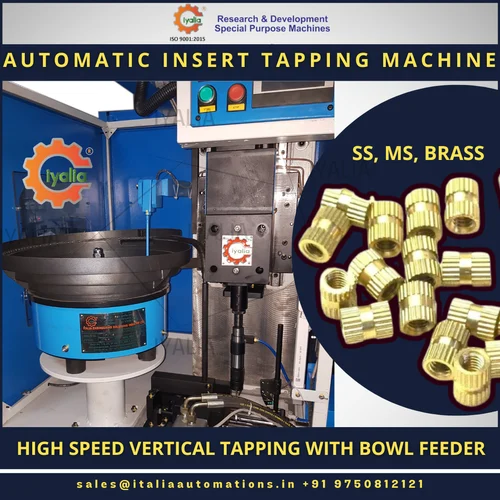

Introducing Servo-Based Single & Multi-Spindle Tapping Machines

Servo-based tapping machines redefine efficiency with high-speed automation, precision control, and adaptability to diverse part specifications. These machines drastically improve production rates while ensuring consistent thread quality and reduced defects.

Key Features of Servo-Based Nut Tapping Machines

�� Ultra-Fast Tapping Speeds – Tap M6 holes up to 10 mm depth in just 3–4 seconds, reducing cycle times significantly.

�� Servo-Controlled Accuracy – Advanced servo motors provide precise speed and torque control, eliminating inconsistencies and scrap.

�� Multi-Spindle Efficiency – Tap multiple holes simultaneously, boosting throughput without sacrificing precision.

�� User-Friendly Interface – A simple, intuitive control panel allows for quick adjustments, reducing downtime.

�� Robust Industrial Build – Built to withstand high-production environments, ensuring reliability and long-term performance.

How Servo-Based Tapping Machines Improve Production Efficiency

✔ Consistent Thread Quality – Precision servo motors ensure every tapped hole meets strict quality standards, reducing rework.

✔ Faster Cycle Times – Boost productivity with rapid tapping speeds, ideal for large-scale manufacturing.

✔ Lower Labor Costs – Automation enables a single operator to oversee multiple machines, cutting workforce expenses.

✔ Versatility Across Nut Sizes – Easily adjustable for different nut specifications, reducing the need for multiple machines.

✔ Real-Time Data & Analytics – Integrated CNC and servo controls provide performance tracking, ensuring optimal machine uptime.

Why Choose Servo-Based Tapping Machines?

Investing in servo-based single and multi-spindle nut tapping machines means higher productivity, superior thread quality, and reduced production costs. Whether you're a manufacturer in automotive, aerospace, or consumer electronics, upgrading to high-speed, precision-driven tapping technology is the key to staying ahead in today's competitive landscape.

Looking to Enhance Your Nut Tapping Efficiency?

Contact us today to learn how our servo-based tapping machines can revolutionize your production line!

Send Message