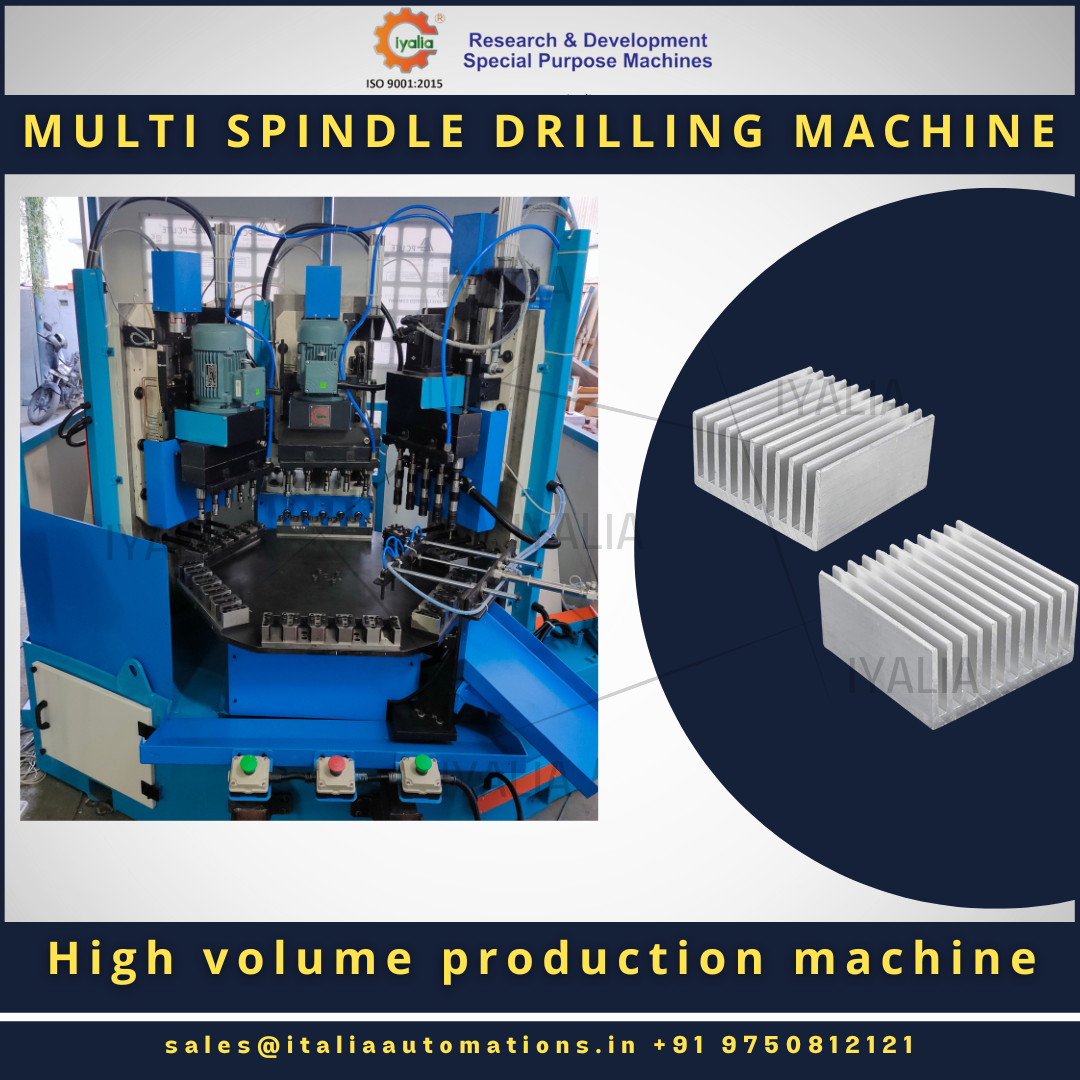

The IYALIA Multi-Spindle Drilling and Tapping Machine is vital for optimizing manufacturing processes. This specialized machine is meticulously designed to perform multiple drilling and tapping operations simultaneously, enhancing operational efficiency and reducing manufacturing costs. Its precise indexing and positioning capabilities ensure accurate alignment of drill and tapping heads, facilitating seamless operation.

The machine features an integrated production progress tracking system, enabling real-time monitoring and analysis, further boosting productivity and cost-effectiveness. It is particularly well-suited for high-volume production, consistently providing precision and quality control. Additionally, its versatility allows for customization to meet diverse production needs, making it an invaluable asset for various manufacturing requirements.

Despite the initial investment, the machine's long-term cost efficiency and increased output offer excellent value for businesses aiming to maximize their manufacturing capabilities. The IYALIA Multi-Spindle Drilling and Tapping Machine is not just an investment in equipment but an investment in superior manufacturing efficiency and productivity.

Key Features and Benefits:

Simultaneous Operations: Performs multiple drilling and tapping operations simultaneously, reducing production time and costs.

Precise Indexing and Positioning: Ensures accurate alignment, enhancing the quality of operations.

Real-Time Monitoring: The integrated system tracks production progress, improving productivity and quality control.

High-Volume Production: Designed for large-scale manufacturing, providing consistent precision and reliability.

Versatility: Customizable to accommodate various materials, geometries, and hole sizes, adaptable to diverse production needs.

Cost Efficiency: Although it requires an initial investment, the long-term benefits of increased productivity and reduced operational costs make it a valuable addition to any manufacturing setup.

Businesses can significantly improve their manufacturing processes by investing in the IYALIA Multi-Spindle Drilling and Tapping Machine, ensuring better efficiency, precision, and overall cost-effectiveness.

Keywords

output

analysis

equipment

geometries

businesses

hole sizes

versatility

reliability

Key Features

tapping heads

customization

quality control

Tapping Machine

excellent value

production time

precise indexing

multiple drilling

integrated system

various materials

valuable addition

long-term benefits

tapping operations

accurate alignment

initial investment

seamless operation

manufacturing setup

specialized machine

manufacturing costs

consistent precision

real-time monitoring

operational efficiency

high-volume production

increased productivity

manufacturing processes

Simultaneous Operations

positioning capabilities

diverse production needs

large-scale manufacturing

long-term cost efficiency

reduced operational costs

manufacturing capabilities

overall cost-effectiveness

superior manufacturing efficiency

The IYALIA Multi-Spindle Drilling

various manufacturing requirements

integrated production progress tracking system