Tapping Machine for Mould Insert

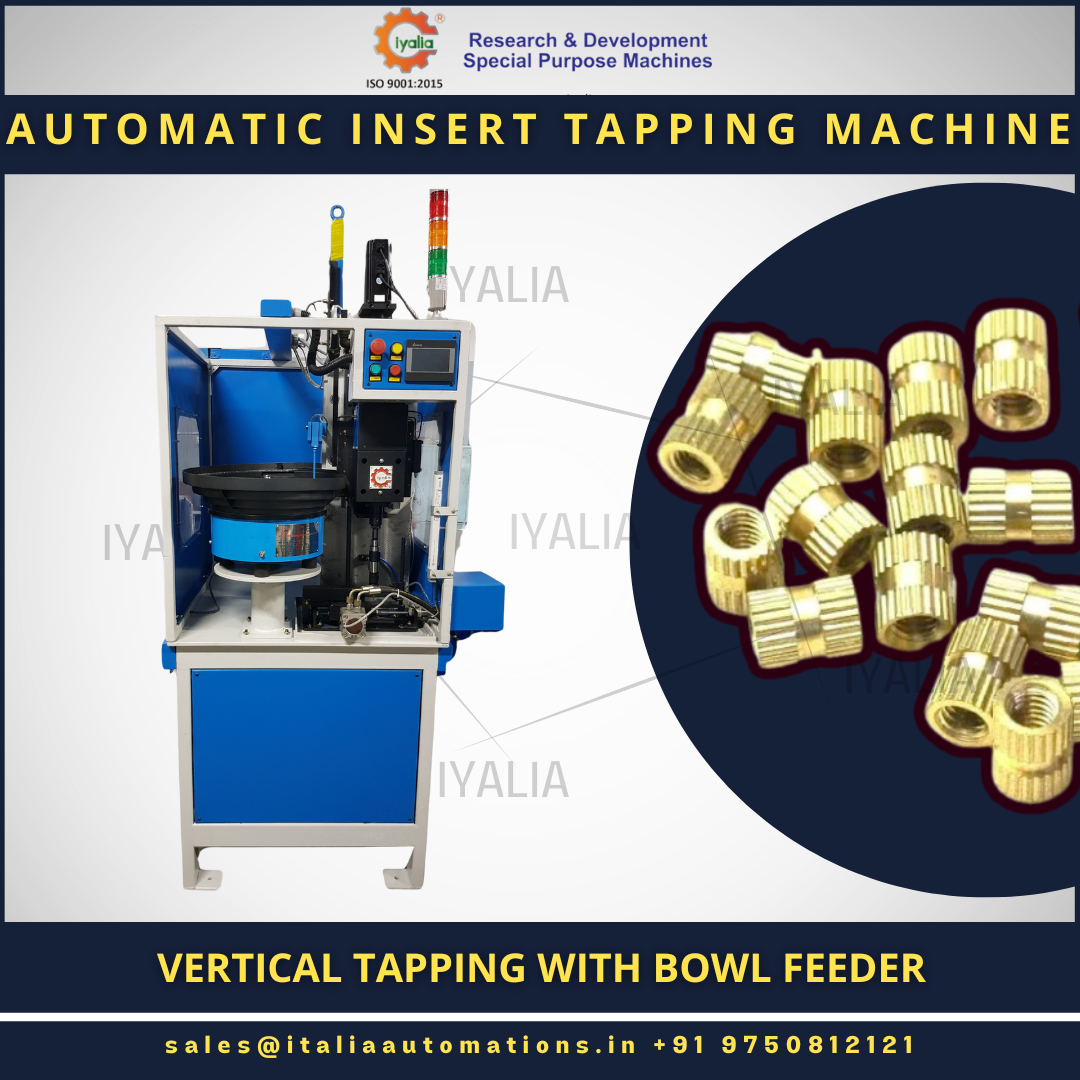

Introducing the Mould Insert Tapping Machine - a high-speed, fully automatic tapping machine that produces threaded parts in just 3 seconds. With its advanced servo controls and spindle rotation resynced technology, you can be sure of a precise pitch control system and the fastest production rate.

The machine has a bowl feeder system that automatically feeds the parts, and the vibration moves them to the next stage. The components move down with gravity through a tube and are transferred to the fixture, where the tapping spindle runs at 3000 RPM. The tapping process takes just 1 second, and the machine has a coolant system that cools the cutting tool to prevent thread formation issues.

In the event of a power failure, the machine spindle stops, and the following two parts are pushed into a separate bin for inspection. This ensures that only threaded parts are in the OK bin and no rejection part goes into the production line.

The IYALIA SPM Tapping Machine is an efficient and reliable solution for your tapping needs. With its automatic operation and quality control measures, you can trust that your production is in good hands.

Keywords

tube

event

OK bin

fixture

gravity

1 second

3000 RPM

efficient

following

vibration

3 seconds

two parts

good hands

components

inspection

technology

next stage

separate bin

cutting tool

power failure

tapping needs

rejection part

threaded parts

coolant system

tapping process

tapping spindle

production line

machine spindle

spindle rotation

reliable solution

bowl feeder system

automatic operation

fastest production rate

thread formation issues

advanced servo controls

quality control measures

Mould Insert Tapping Machine

precise pitch control system

The IYALIA SPM Tapping Machine

high-speed, fully automatic tapping machine