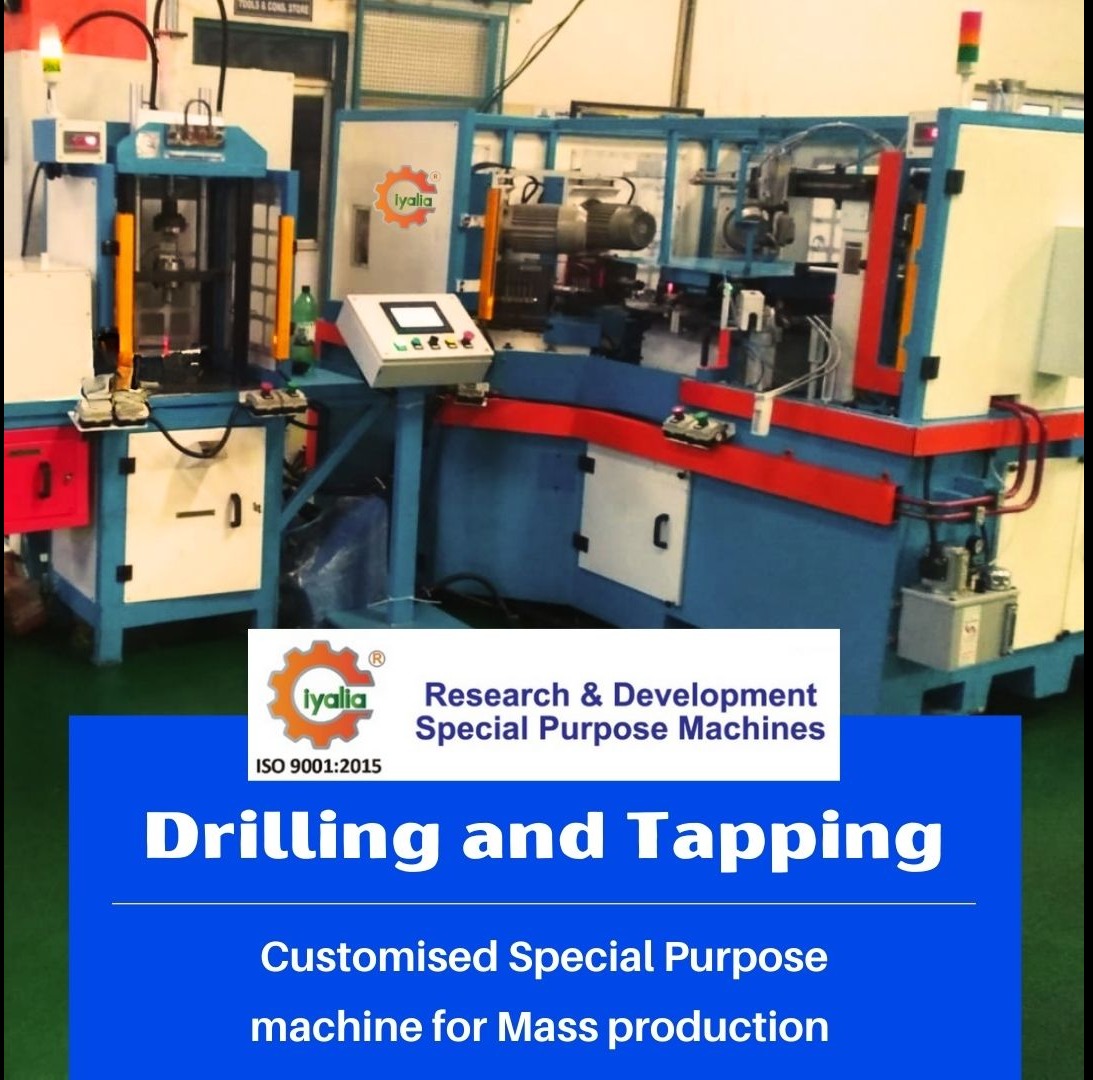

Considering the implementation of IYALIA Special Purpose Drilling and Tapping Machines (SPM) from the perspective of space saving and productivity enhancement provides a unique and insightful view into modern manufacturing efficiencies.

Space economy is a critical aspect of manufacturing efficiency, especially in urban environments where industrial space is at a premium. SPM machines, with their specialized design, offer a significant advantage in this regard. These machines are tailored to perform specific tasks precisely, often allowing them to be more compact than conventional, multi-purpose machinery. This compactness means that they occupy less floor space in a manufacturing facility, allowing for a more efficient layout and the opportunity to utilize space for other productive purposes or even to reduce the facility's overall footprint.

Moreover, integrating SPMs into a production line can lead to reorganising workflow and processes. Traditional production lines, with large, bulky machines and conveyors, often require a lot of space for the equipment and moving materials and personnel. SPMs, being more streamlined and efficient, can lead to a more compact and optimized production layout. This space efficiency is not merely a matter of saving square footage; it translates into reduced movement within the plant, which can significantly cut down on time between processes and enhance overall operational efficiency.

In addition to space savings, the productivity aspect of SPM machines is paramount. These machines are designed for high-speed operation and precision, leading to an increase in the volume of production without a proportional increase in space usage. For instance, a single SPM designed for a specific drilling and tapping operation can replace multiple general-purpose machines, leading to a higher output in a smaller area. This increase in the density of production capability is crucial for businesses looking to maximize their output in limited spaces.

Furthermore, the space efficiency of SPMs can have secondary benefits, such as reduced energy consumption per unit of production. A more compact facility with an optimized machine layout tends to have lower energy requirements for heating, cooling, and lighting, further enhancing the overall efficiency and sustainability of the operation.

Lastly, there's a significant impact on inventory management. With faster production cycles enabled by SPMs, the need for large storage spaces for raw materials and finished products is reduced. This just-in-time production approach minimizes the space needed for inventory, further optimizing the use of available space.

In summary, integrating Special Purpose Drilling and Tapping Machines in a manufacturing setup enhances productivity and significantly contributes to space efficiency. This dual benefit is particularly crucial in the contemporary industrial landscape, where space and efficiency are key determinants of competitive advantage and profitability.

Keywords

use

lot

need

SPMs

plant

unique

volume

matter

regard

density

cooling

summary

premium

heating

instance

workflow

lighting

addition

personnel

precision

processes

conveyors

equipment

businesses

single SPM

opportunity

perspective

space usage

compactness

dual benefit

SPM machines

space saving

smaller area

profitability

higher output

raw materials

Space economy

sustainability

limited spaces

machine layout

implementation

specific tasks

square footage

critical aspect

insightful view

available space

key determinants

compact facility

efficient layout

reduced movement

industrial space

Tapping Machines

space efficiency

moving materials

less floor space

specific drilling

tapping operation

finished products

overall footprint

specialized design

significant impact

urban environments

secondary benefits

overall efficiency

productivity aspect

manufacturing setup

high-speed operation

large storage spaces

inventory management

significant advantage

production capability

large, bulky machines

competitive advantage

proportional increase

manufacturing facility

manufacturing efficiency

time production approach

faster production cycles

productivity enhancement

lower energy requirements

other productive purposes

reduced energy consumption

optimized production layout

Traditional production lines

overall operational efficiency

IYALIA Special Purpose Drilling

multiple general-purpose machines

modern manufacturing efficiencies

contemporary industrial landscape

conventional, multi-purpose machinery