Cold forging process for small parts

Cold forging is a process used to produce high-quality, precision-made parts. It's particularly well-suited for the production of small parts that require high levels of accuracy and repeatability. the process or the steps involved in the cold forging process for small parts:

Material Selection: The first step in the cold forging process is selecting the right material for the part you're producing. The material must be suitable for cold forging, and should have the necessary mechanical properties to meet the requirements of the finished part.

Cutting: Once you've selected your material, it will need to be cut into a suitable length for the cold forging process.

Pre-forming: Pre-forming is the process of shaping the material into a rough approximation of the final shape of the part. This is typically done using a punch and die set.

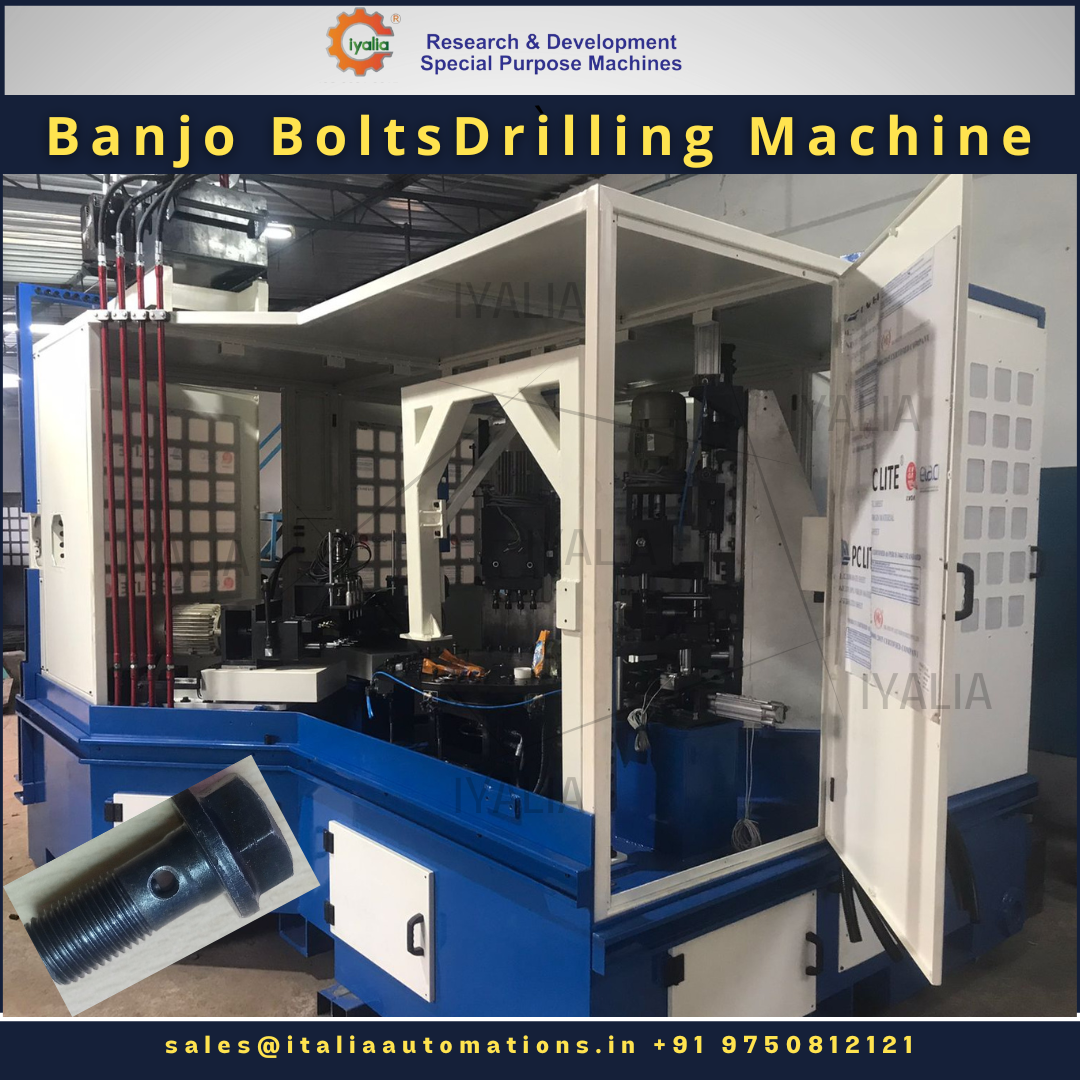

Cold Forging: The next step is to cold forge the pre-formed material. This is done by applying pressure to the material using a cold forging machine. The machine will shape the material into the final form of the part.

Finishing: Once the cold forging process is complete, the part may require some finishing work to remove any rough edges or burrs.

Quality Control: Finally, the finished part must be inspected to ensure it meets the necessary specifications and requirements.

It's important to note that cold forging can be a complex process that requires specialized equipment and expertise.

Youtube Link:- https://youtu.be/7-fCqqtXwjA

If you're not experienced with cold forging, it's recommended that you seek out the services of a professional cold forging company to produce your small parts. They will have the expertise and equipment necessary to produce high-quality parts efficiently and cost-effectively.

Keywords

burrs

punch

steps

Cutting

die set

services

pressure

accuracy

expertise

next step

production

final form

first step

rough edges

high levels

small parts

final shape

Youtube Link

requirements

finished part

repeatability

right material

finishing work

suitable length

Quality Control

complex process

Material Selection

high-quality parts

rough approximation

cold forging machine

Cold forging process

specialized equipment

necessary specifications

necessary mechanical properties

professional cold forging company

high-quality, precision-made parts