Case Study: Revolutionizing Cold Forging with Forging Automation Robotics

Introduction:

This case study delves into the journey of a customer facing significant challenges in the cold forging industry, primarily concerning low productivity and workforce issues. By implementing forging Automation and robotics, the company aimed to revolutionize their cold forging process, enhance efficiency, and address workforce constraints.

Background of our customer:

The customer, a prominent player in the cold forging parts manufacturing industry, specializes in producing various automotive parts through cold forging. Cold forging, performed at room temperature, offers the advantage of producing stronger parts with superior surface finish and dimensional control. However, the customer was grappling with exceedingly low productivity rates and the high labour intensity of the process, which affected their market competitiveness and profitability.

Challenge:

The key challenges faced by the customer included:

Low Productivity: The manual cold forging process was time-consuming and could not meet the rising market demand.

Manpower Challenge: Skilled labour was necessary for quality control and operational management, leading to high labour costs and dependency.

Consistency and Quality Issues: Manual operations led to variability in the product quality, affecting the overall brand reputation.

Safety Concerns: The physical nature of cold forging posed safety risks to the workforce.

Solution:

To address these challenges, the customer partnered with IYALIA Engineering, automation provider to integrate forging automation robotics into their cold forging process. The solution involved several key components:

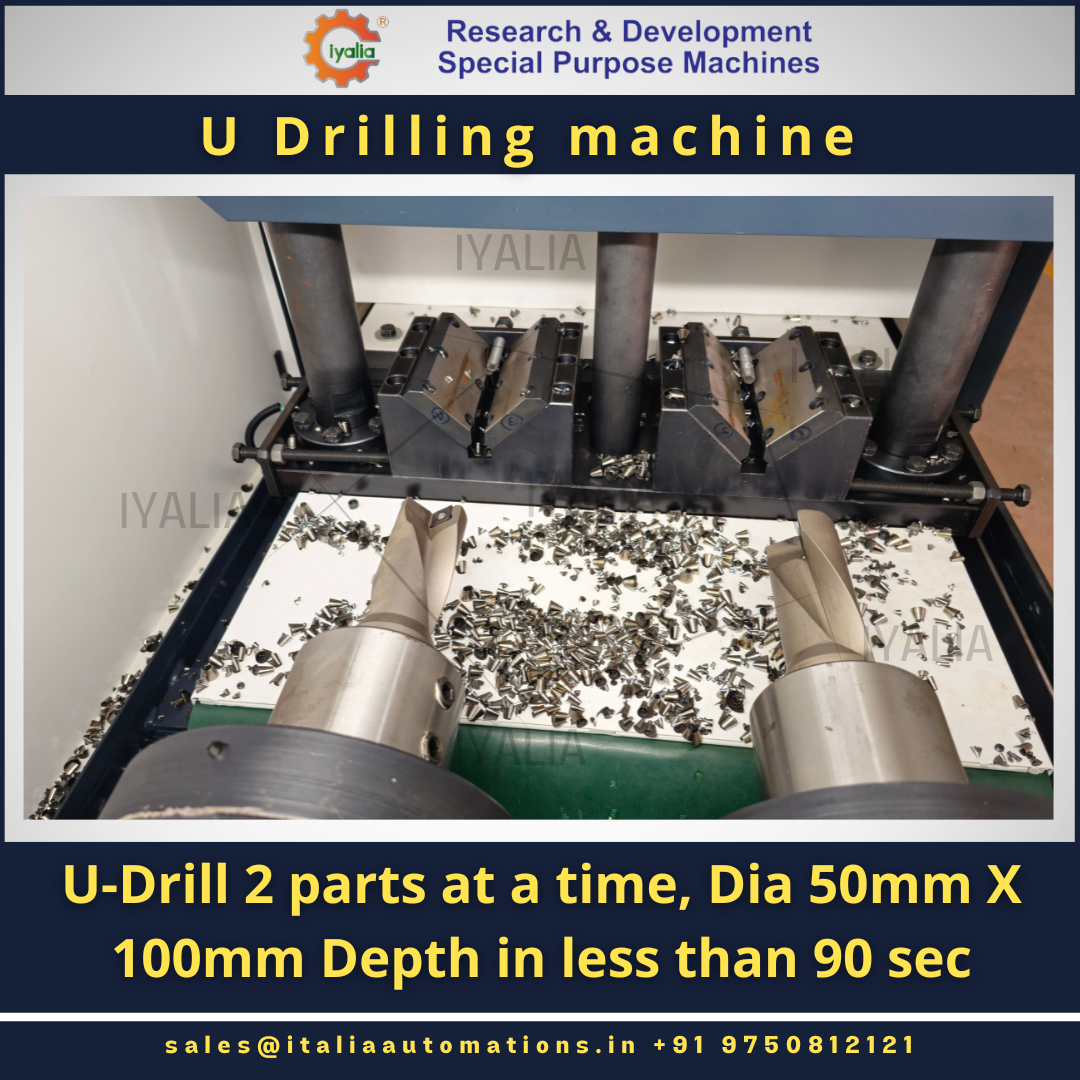

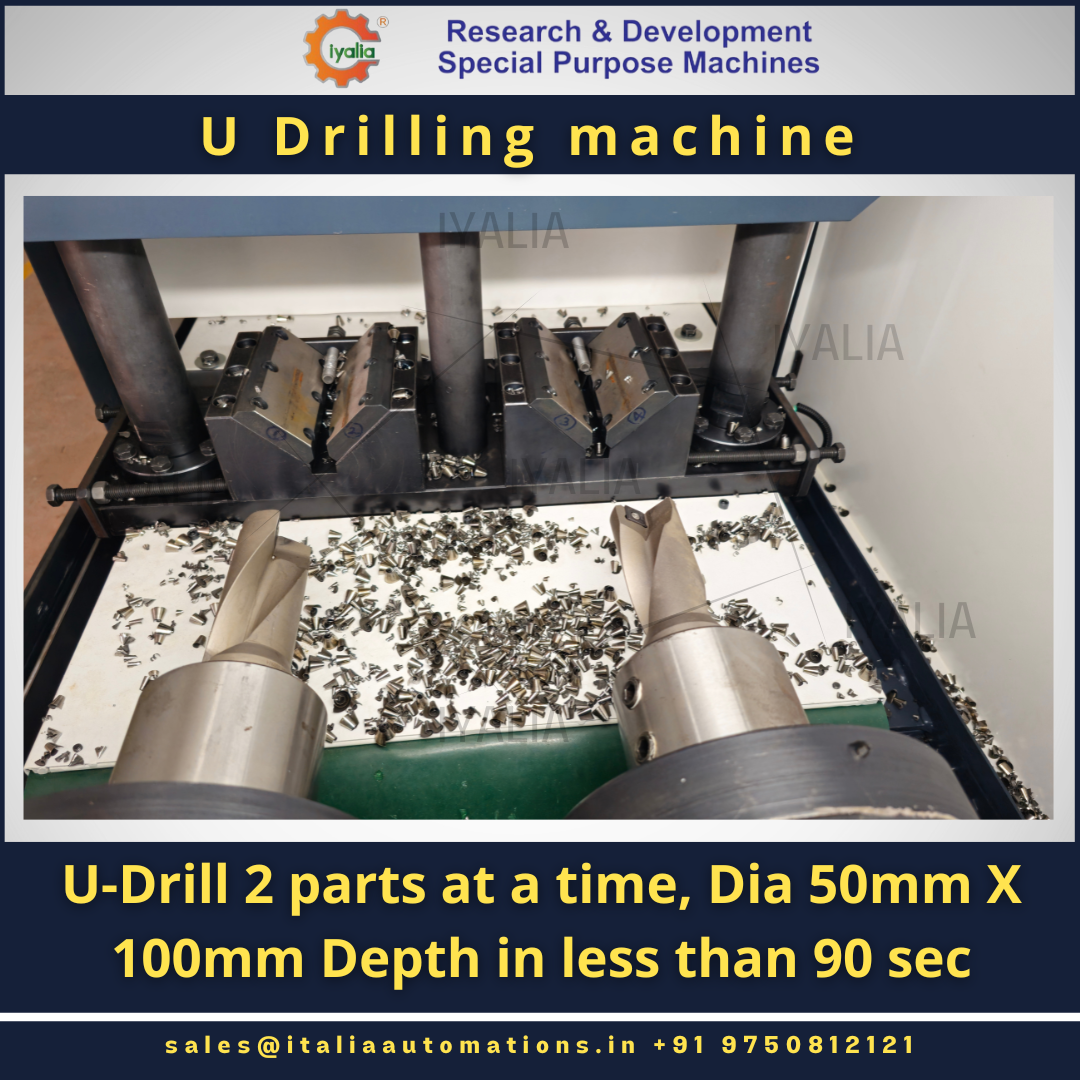

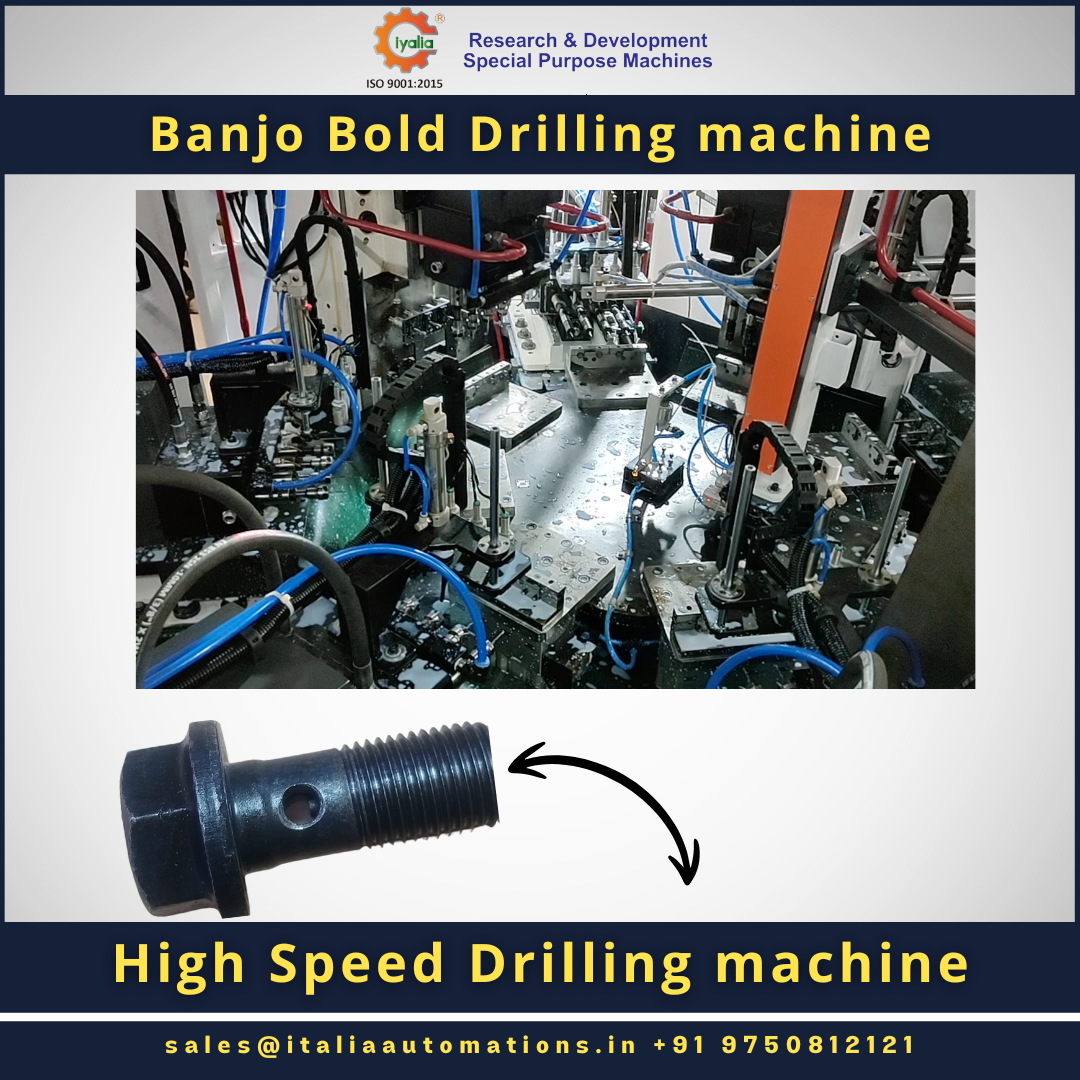

Automated Material Handling: Implementing conveyors and robotic arms for transporting raw materials and finished parts, reducing manual labour and enhancing speed.

Robotic Forging Machines: Introducing robots capable of applying precise force, ensuring consistent and high-quality output.

Quality Control Automation: Integrating automated inspection systems to ensure each part meets the required specifications, reducing the reliance on manual inspection.

Data Collection and Analysis: Employing sensors and data analytics tools to monitor process parameters like temperature and pressure, enabling real-time process optimization.

Implementation:

The implementation phase involved:

Initial Assessment: Conducting a thorough analysis of the existing process to identify automation opportunities.

Customized Solution Design: Tailoring the automation and robotics system to meet the specific needs of the cold forging process.

Installation and Integration: Setting up the equipment and software while ensuring minimal disruption to ongoing operations.

Training and Support: Providing comprehensive training to the staff and ongoing technical support to ensure a smooth transition.

Results:

The integration of forging Automation and robotics led to transformative outcomes:

Productivity Surge: Production rates increased significantly, with the ability to meet and exceed market demand.

Reduced Labor Costs: The dependency on skilled labour decreased, resulting in substantial cost savings and reduced operational risks.

Enhanced Quality and Consistency: The precision of robotics ensured that every part met high-quality standards consistently.

Improved Safety: Automating the hazardous aspects of forging reduced workplace accidents and enhanced overall safety.

Conclusion:

Introducing forging Automation and robotics marked a turning point for the customer, enabling them to overcome their cold forging challenges. The increase in productivity, reduction in labour costs, and improvements in quality and safety underscored the transformative power of Automation in the manufacturing sector. This case study serves as a testament to the potential of forging automation robotics to revolutionize industry practices and set new benchmarks for efficiency and excellence. While the initial investment was significant, the long-term benefits and competitive edge gained made it a strategic and forward-thinking decision.

Keywords

speed

staff

robots

forward

sensors

journey

Results

company

reliance

increase

software

pressure

customer

advantage

equipment

precision

reduction

testament

potential

conveyors

excellence

efficiency

Case Study

dependency

consistent

parameters

Conclusion

Background

variability

Integration

Consistency

safety risks

Introduction

robotic arms

Installation

improvements

turning point

precise force

raw materials

profitability

manual labour

overall safety

new benchmarks

stronger parts

finished parts

Quality Issues

Skilled labour

specific needs

key challenges

Improved Safety

robotics system

Safety Concerns

Data Collection

physical nature

product quality

room temperature

competitive edge

existing process

Production rates

Enhanced Quality

workforce issues

prominent player

high labour costs

thinking decision

manual inspection

Manual operations

operational risks

smooth transition

hazardous aspects

thorough analysis

Manpower Challenge

Productivity Surge

long-term benefits

initial investment

industry practices

ongoing operations

IYALIA Engineering

Initial Assessment

minimal disruption

automation provider

high-quality output

dimensional control

Reduced Labor Costs

data analytics tools

rising market demand

implementation phase

transformative power

manufacturing sector

high labour intensity

cold forging industry

workforce constraints

several key components

low productivity rates

comprehensive training

market competitiveness

significant challenges

operational management

high-quality standards

cold forging challenges

superior surface finish

transformative outcomes

required specifications

various automotive parts

Robotic Forging Machines

substantial cost savings

overall brand reputation

automation opportunities

ongoing technical support

Quality Control Automation

Customized Solution Design

Automated Material Handling

Forging Automation Robotics

manual cold forging process

reduced workplace accidents

automated inspection systems

real-time process optimization

cold forging parts manufacturing industry