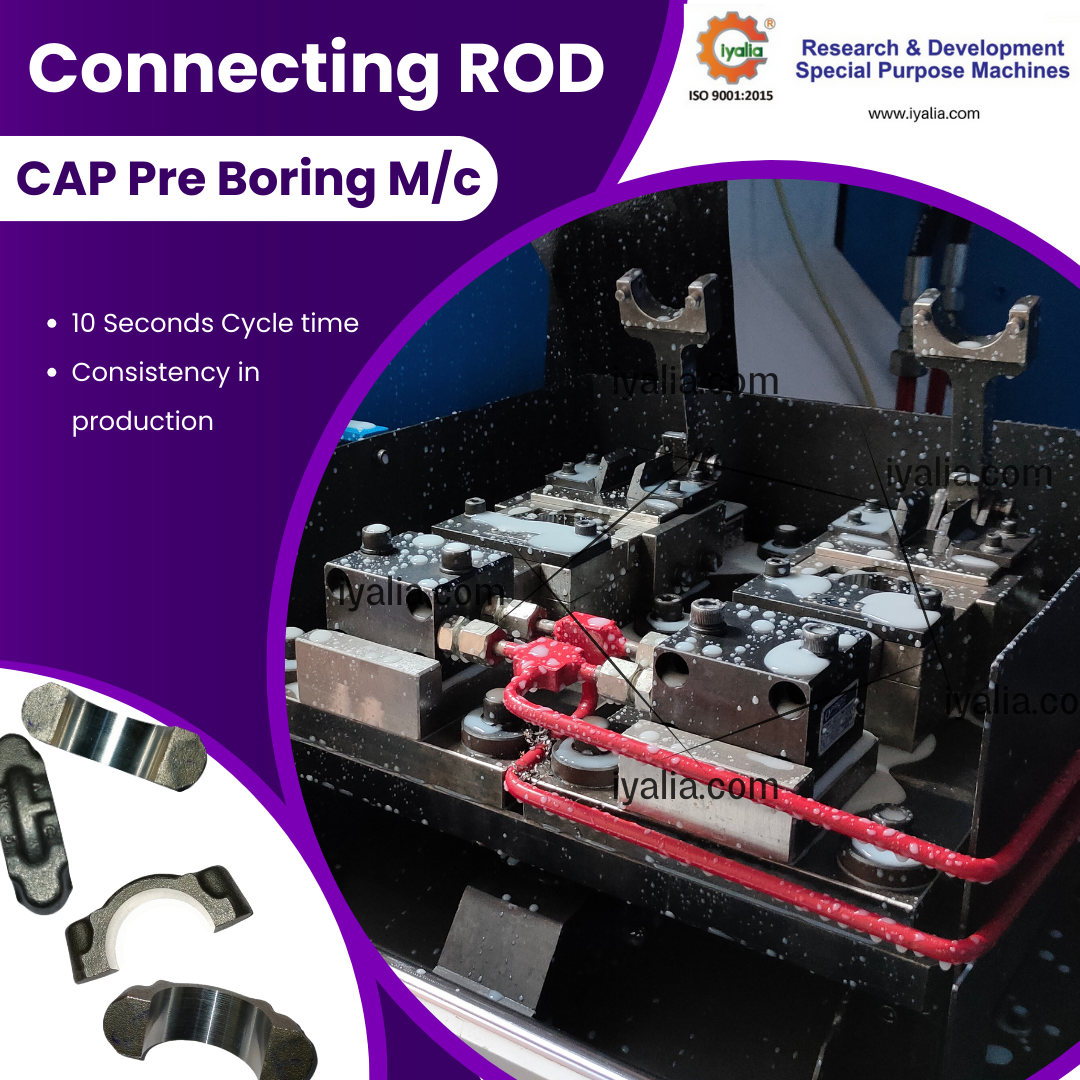

Introduction In high-stakes manufacturing, connecting rod production demands precision, efficiency, and reliability. Our state-of-the-art SPM Pre-Boring machine is engineered to meet these challenges head-on, revolutionizing how connecting rods are made. With advanced forging and machining capabilities, our IYALIA SPM machine ensures that every component meets the highest quality and performance standards. Unmatched Precision and Consistency The connecting rod, a critical component in many types of machinery, must be produced with the utmost precision. Our SPM Pre-Boring machine leverages dual spindles and four fixtures to guarantee exactness in bore centring, wall thickness, finish, and dimensional consistency. This precision ensures that each connecting rod part meets strict specifications, enhancing the overall performance and longevity of the machinery they are part of. Innovative Design for Maximum Efficiency Efficiency in manufacturing not only saves time but also reduces costs. Our machine's innovative design features two spindles and four fixtures strategically positioned on both sides of the machine. This unique setup allows for continuous operation; while parts are loaded on one side, machining occurs simultaneously on the other. This seamless process eliminates downtime associated with loading and unloading, significantly boosting production rates. Zero Idle Time for Optimal Productivity Reducing idle time is critical to enhancing productivity in any manufacturing process. The SPM Pre-Boring machine is designed with this in mind. Its dynamic fixture movement and efficient tooling system ensure that idle time is completely eliminated. As a result, the machine maintains a constant production flow, enabling faster turnaround times and higher output without compromising quality. Conclusion For manufacturers looking to elevate the production of connecting rods, our SPM Pre-Boring machine offers the perfect solution. Combining precision, efficiency, and innovative design sets a new standard in manufacturing excellence. Embrace the future of connecting rod production with a machine that promises to meet and exceed your expectations. Call to Action Are you interested in learning more about how our SPM Pre-Boring machine can transform your manufacturing process? Contact us today for a detailed consultation and see the difference in efficiency and quality our technology can bring to your production line.

Send Message